Tubeless Tire FAQ

Car and motorcycle tires have been tubeless for decades, but bicycle tires have continued to use tubes. That changed during the 2010s, when first mountain bikers and then the riders of all-road and gravel bikes started to experiment with tubeless technology. They reason was simple: If you could run your tires tubeless, you’d be able to ride lower pressures and not worry about pinch flats even in very rough terrain. An added advantage of tubeless is indirect: The sealant required to make the tires airtight on the rim also seals small punctures, so flats can be much less frequent with tubeless tires.

At first, tubeless bicycle tires were very much hit-or-miss: classic rims were converted to tubeless installations, but on seemingly every other ride, the tires burped or mysteriously went flat. Those problems are behind us, and tubeless technology is maturing. These days, many riders run their tires tubeless without problems.

Most Rene Herse tires are tubeless-compatible, giving you a choice of running them with tubes or tubeless. Running supple bicycle tires tubeless is a relatively new technology, and our understanding keeps evolving. To build this FAQ, we talked to customers, bike shops and racers to identify the most common questions about tubeless tires:

How are tubeless-compatible tires different from ‘standard tires’?

The main difference is in the bead shape. The bead of a tubeless-compatible tire is designed to form an airtight seal against the rim. The bead of a standard tire is only designed to hold the tire on the rim. Almost all Rene Herse tires wider than 32 mm are tubeless-compatible. They package shows if a Rene Herse tires is ‘Tubeless Compatible.’

What is the difference between ‘tubeless-ready’ and ‘tubeless-compatible’ tires?

Tubeless-ready tires are airtight, so they don’t need sealant for tubeless installation. To achieve this, they have more rubber on the sidewalls or even an extra airtight layer in the casing. This makes them stiffer, heavier and less supple. Translated into the real world, that means ‘tubeless-ready’ tires are slower and less comfortable than their standard counterparts.

Fortunately, there’s a way to preserve the speed and comfort of supple tires when running them tubeless. Tubeless-compatible tires don’t have airtight sidewalls. That way, they can be as supple as ‘standard’ tires. They require sealant to become airtight.

What makes a rim tubeless-compatible?

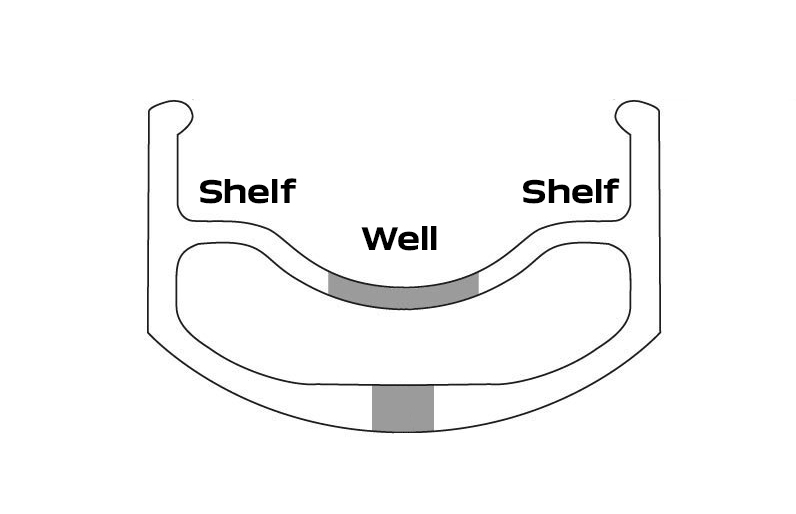

All rims have a well, which has a smaller diameter to allow the tire bead to become slack when you mount the tire. The bead needs to be slack so you can lift it over the rim wall. (Tire beads don’t stretch much, otherwise, the tire wouldn’t stay on the rim.)

On a classic rim (above), the well extends all the way to the sidewalls. This allows the tire to seat automatically as you inflate it, and move back into the center of the well when you let out the air. This makes tire mounting and removal easy.

A tubeless-compatible rim has flat shelves next to the sidewall. The bead rests on the shelf and doesn’t move easily. This prevents the tire from burping – a sudden loss of air when the tire deforms so much that it loses contact with the rim sidewall.

To mount or remove the tire, you have to push the bead into the well by hand. If the bead is on the shelf anywhere around its circumference, the tire becomes almost impossible to mount or remove. This means that a little extra care is required when mounting or removing a tire from a tubeless-compatible rim.

Can I run tubes in tubeless-compatible tires?

Absolutely. Tubeless-compatible tires and tubeless-compatible rims are 100% compatible with tubes. If you run tubes, you also can mix tubeless-compatible tires with ‘classic’ rims and vice versa.

Tubeless-compatible rims have the advantage that the tire usually stays on the shelf even when you have a sudden flat, making it much less likely that the tire comes off the rim and causes a crash.

What about Road Tubeless?

Tubeless technology works great for mountain bikes, where the tires are relatively stiff and pressures are low. For all-road and gravel bikes, we’ve also mastered the technology. Even with their supple sidewalls, the wider Rene Herse tires work well tubeless.

Road tires run at high pressures, and that presents a number of problems. The forces at the rim/tire interface are much greater with tubeless installation, because there is no tube that reinforces that interface.

This means that tubeless-compatible road rims must have stronger sidewalls than ‘classic’ rims. Many were surprised when Roval introduced ultralight rims that are not tubeless-compatible. The reason for this seemingly retrograde spec is simple: It allows the rims to be lighter than they could be if they were tubeless-compatible.

The same applies to the tires. A supple tire has much less stiffness in the casing. It relies almost entirely on the bead to keep the tire on the rim. And it’s difficult to make a bead that a) stays on the rim even at very high pressures and b) still allows the tire to be installed and removed with relative ease.

It’s possible to make tubeless tires and rims for road bikes, but you almost inevitably end up with tires that are stiffer and rims that are heavier than their non-tubeless counterparts.

The technology is evolving. In the future, we’ll probably see tubeless-compatible Rene Herse tires with ultra-supple casings even in widths narrower than 35 mm. (Most of our tires ≥35 mm wide are already tubeless-compatible.)

What are the advantages of road tubeless?

There aren’t any real advantages on the road. Tubeless tires don’t pinch flat, but that has become almost a non-issue on the road as riders have moved to wider tires. The sealant inside the tires also seals most punctures, but many riders use sealant inside their tubes and report good results. Most of all, if you take your road bike on gravel, you’d probably want to set up the tires tubeless (and run the widest tires you can fit).

Are tubeless tires slower than tires with tubes?

Tubeless-compatible tires have liquid sealant inside, which increases their resistance. On the other hand, there is no tube inside the tire, which reduces the resistance. Bicycle Quarterly’s research has shown that the two effects cancel each other: Setting up your tires tubeless makes them neither faster nor slower than running tubes.

Tubeless tires that don’t require sealant have more rubber on the sidewalls to make them 100% airtight. This makes them slower than supple tires that don’t have thick, airtight sidewalls.

Why do tubeless tires not always seal when it’s almost freezing out?

Most sealants use latex to seal the tire. Latex doesn’t cure when it’s very cold. (If you’ve ever tried painting your house when it’s very cold out, you know!) If you have a puncture on a tubeless tire during a mid-winter ride, the sealant may not work.

Are Rene Herse tires safe with hookless rims?

Most modern carbon rims are hookless because making a hook from carbon is difficult. It requires a complex mold with many moving parts, and this makes it harder to control the diameter of the rim. Hookless rims can be made with simpler molds, and their diameter has less variability. This improves the tire fit.

Aluminum rims are rolled from straight extrusions, so their diameter inevitably has greater tolerances. Fortunately, it’s easy to put a hook on the extrusion, which provides additional ‘insurance’ to keep the tire on the rim.

If you run tubes, the tolerances between tire and rim can be quite generous, and most hookless rims work with supple tires like our Rene Herse models.

When you install your tires tubeless, the tolerances have to be much tighter. As long as your rims meet the ISO/ETRTO standards, they’ll work fine with Rene Herse tires. If your rims are not to spec, we don’t recommend using them. Check out this post for more information and measurements of a variety of popular rims.

Why do many riders first install a tube, before running the tire tubeless?

A tube pushes the rim tape into place and makes sure it adheres properly to the rim. This prevents sealant from seeking between rim and tape and dislodging the tape – which allows air to escape through the rim’s spoke holes… (Also make sure to wipe off the rim with alcohol before installing the tape to remove all oils and residue from the manufacturing process.)

Installing the tire with a tube also seats the beads. When you remove the tube, you have to unseat only one bead, so it’s easier to seat the tire when you inflate it.

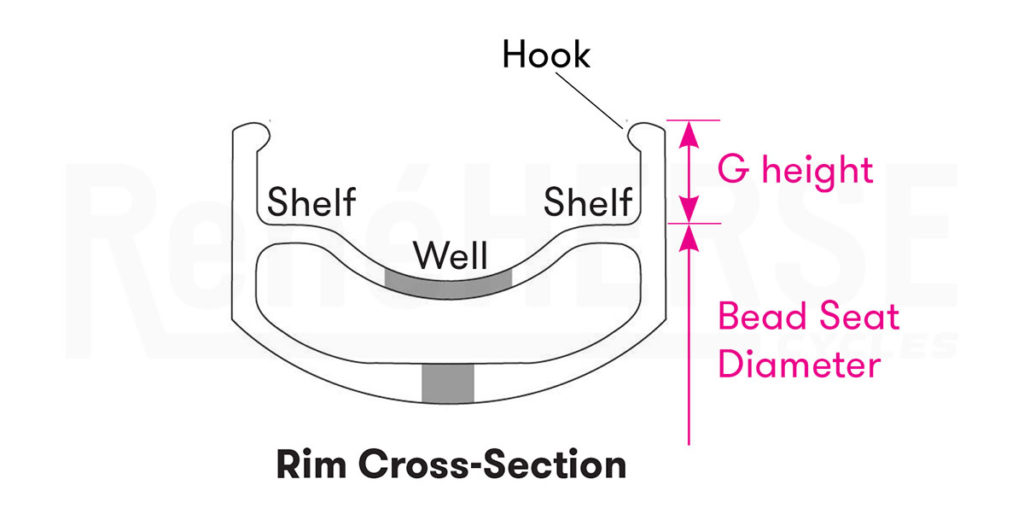

When you install a tire with a tube, it’s easy to check the tire fit on the rim. If the tire seats at a relatively low pressure (<40 psi/2.8 bar), the rim’s bead seat diameter (BSD) is likely too small. Do not use this rim with tubeless tires. The tire can blow off the rim! (Also measure the G height to make sure it meets ETRTO standards.)

Is there a direction for the rim tape?

Some riders also recommended to wrap the rim tape in the opposite direction of the wheel rotation. As the tire rotates, the sealant won’t dislodge the edge at the end of the tape. Instead it’s flows over the edge. (You want a tiny waterfall at the tape edge, not a dam.)

Why do supple tires require extra care during tubeless setup?

A supple tire’s casing is less stiff, and it can move ever so slightly on the rim. This means that air can escape at the tire/rim interface unless sealant is present to stop these leaks. When you install supple tires tubeless, make sure to distribute the sealant all the way around the tire and to work it into the tire/rim interface everywhere. Simply installing the tire, pouring in some sealant and going for a ride isn’t enough. Refer to our step-by-step instructions on installing tubeless tires (linked at the end of this post).

Supple tires have sidewalls that are coated with as little rubber as possible, because extra rubber makes the tire stiffer and slower. This makes supple tires more porous than stiffer tires. It’s important to shake your sealant for a full 60 seconds (a long time!) to distribute the solids that seal the tire. Using the right sealant also helps: We recommend SmartSeal sealant, which has been developed specifically for supple tires.

Generally, Rene Herse Endurance and Endurance Plus tires are easiest to seal, because they have an added protection layer that also makes them more airtight. The Standard casing is next, and the Extralight requires a bit more care to seal. Even so, I’ve installed more than 40 Extralight tires tubeless without any trouble – using just a floor pump. It helps to work methodically, but it’s not too difficult.

In very rare cases, the sidewalls can leak even if you do everything right, because the rubber coating is just a hair too thin. These tires are the most supple (fastest when you run them with tubes), but they don’t work well tubeless. If the sidewalls leak even after you’ve done everything correctly, that is covered by our warranty.

The ride quality and speed you get from supple tires – especially on rough terrain – is well worth the extra care required during tubeless setup.

How much sealant do I need in my tires?

More than you may think! The general recommendations are:

- 26-32 mm wide tires: 60-90 ml (2-3 oz)

- 35-44 mm tires: 90-120 ml (3-4 oz)

- 45+ mm tires: 120-150 ml (4-5 oz)

Some riders report that they can get away with much less sealant. If the fit between your rim and tire is very tight, you may not need as much sealant. However, if all your sealant is absorbed by the tire casing, or if it dries out, the tire can suddenly break loose from the rim wall and lose all its air.

Also remember to top up the sealant at least once a month, because it tends to dry out over time.

If you have doubts how much sealant remains in your tires, you can unscrew the valve, then rotate the tire so the valve is at the bottom, and use a ‘dipstick’ (a long match works) to make sure that liquid sealant remains in the tire (similar to checking the oil level in a car). There should be a pool a few millimeters deep at the bottom of the wheel, not just a trace of liquid.

Is the tire pressure different when I run tubeless vs. with tubes?

Without a tube, the tire has a little less internal stiffness, so to get the same feel, you’ll have to run slightly higher pressures. In real life, this effect is too small to make a noticeable difference. Mostly, you can run lower pressures with tubeless tires because you don’t have to worry about pinch flats. Don’t go overboard, though: If you bottom out too hard, you can still destroy the tire and the rim. And if you run your tires at pressures that are too low, the sidewalls will start to break down prematurely.

There is a difference in maximum pressure: Don’t exceed 60 psi when running Rene Herse tires tubeless, even if your tire and rim are rated for a higher pressure with tubes. If the maximum pressure rating of rim or tire is lower than 60 psi, use the lower of the values.

Why do tubeless tires sometimes leak once they reach very high mileages?

Tire sidewalls flex with each revolution of the wheel as the tire compresses where it touches the road. Over time, this constant kneading can make the rubber of the casing porous, and the tire will no longer seal. You can still run the tire with tubes, or you can replace it, because it’s nearing the end of its lifespan anyhow. That is also the reason why you should use only new tires for tubeless installations – casings that have seen significant mileage will be much harder to seal.

My tubeless tire blew off the rim. What happened?

Oh no! A tire blowing off the rim is very dangerous. It’s rarely the tire’s fault – the bead diameter of Rene Herse tires is very consistent, as was confirmed when Enve tested a large number of Rene Herse tires for compatibility with their hookless rims. (They passed with flying colors.)

Usually the problem is a slightly undersize rim. If the bead seat diameter (BSD) is smaller than the ETRTO standard requires, the tire won’t seat properly. You can build up the rim bed with extra rim tape if it’s just a small difference and your rim’s G height is not undersize. Otherwise, run your tire with tubes on this rim.

Make sure your rims are not too wide for your tires. Blow-off risk! For more information, check www.renehersecycles.com/tech-info/tires/

Always check that there is enough sealant in your tire. If the sealant has dried out, your tire is more likely to burp and come off the rim. This can cause a crash!

But I’ve run other, less supple tires on the same rim without problems. Why doesn’t this rim work with supple tires?

Supple tires have a much lower casing stiffness. That means that they rely almost entirely on the strength of the bead to stay on the rim, and the fit must be better than with tires that have stiff sidewalls. That said, Rene Herse tires are designed to be safe on all rims that meet the current ETRTO standards. (See also ‘Further Reading’ at the end of this post.)

Most riders who run their tires tubeless have only good experiences. Others seem to have only bad luck. Why?

It’s important to work methodically when installing tires tubeless. That is why we provide detailed instructions. Beyond that, much of it depends on the fit between tire and rim. If the fit is good, tubeless installation usually is easy, and the tires are safe on the road. If the fit is bad – if the rim is undersize – the tires are very difficult to seat, and they can blow off while you ride.

Is there a way of knowing whether my tubeless installation is safe?

If you have doubts about your rim, install the tire with a tube first. If the tire seats easily at a low pressure (<40 psi/2.8 bar), the rim’s bead seat diameter (BSD) is likely too small. Do not use this rim with tubeless tires. Also measure the G height to make sure it meets ETRTO standards. Don’t insist on running an undersized rim tubeless and risk a blow-out. A pinch flat is far less dangerous, so we recommend using tubes if you have any doubts. For more information and measurements of a variety of popular rims, see this post.

I have a tiny hole or cut in my tire, and sealant leaks out. Is the tire ruined?

It depends on the extent of the damage. We can’t recommend running a tire that has been damaged, but many riders have had good luck putting a tube patch (vulcanizing, not glueless) on the inside of the tire. Wipe the casing with alcohol to clean it thoroughly and lightly sand it to make the patch stick.

What about tubeless installations of tires that aren’t tubeless-compatible?

Maybe you’ve seen Ted King run Stampede Pass 700C x 32s tubeless. It’s doable, and can be safe if you know what you are doing. Officially, we cannot recommend it, and you are on your own if something goes wrong. Make sure not to exceed 60 psi with any tubeless installation.

Do you run the tires on your own bikes tubeless?

It depends. On most rides, I run my tires with tubes, mostly because I don’t like to worry whether the sealant has dried up. However, when I head into truly rough terrain – like the road to Odarumi Pass in the top photo – I run my tires tubeless to avoid pinch flats. I am glad the technology exists, and once mastered, setting up tires tubeless isn’t difficult. I am also glad tubes are still around. I’ve found that both work equally well, and our testing has shown that there is no difference in speed or comfort, either.

Other resources:

- The latest edition of our tire instructions

- Step-by-step guide for installing tires tubeless

- Rim and tire standards, as well as measurements of popular rims

- More technical information about Rene Herse tires