Science and Bicycles: Frame Stiffness

Lightweight frames, made from high-strength tubing, were thought to be stiffer than ordinary frames. They performed better for most cyclists, but the conclusion that stiffer frames were better was erroneous. Eventually, this led the makers of steel bicycles down the wrong path and may have hastened their demise.

When the plague ravaged Europe during the 14th century, people noticed that the disease arrived together with herds of cats. They concluded that the cats brought the disease and responded by killing as many cats as possible. Only much later was it discovered that the plague was transmitted by fleas that lived on rats. Cats arrived with the plague only because they preyed on the rats. So killing the cats actually made things worse, by allowing the rats to multiply.

This reminds me of bicycles and frame stiffness. For decades, riders have assumed that stiffer frames were more efficient, and thus faster. At the same time, physics tells us that a lighter bike is faster uphill and in accelerations. Stiffness and weight are conflicting goals: To make a frame stiffer, you need more material. To make it lighter, you need less material.

There was a apparent solution to this problem: high-strength steels allowed tubing makers to use less material without giving up strength. Reynolds 531 and other modern steel tubes enabled builders to craft lightweight frames. Even though these frames were light, they felt very stiff when the builders bent the tubes to align the frame. Many old builders have told me: “The lightweight Reynolds 531 was twice as stiff as ‘drainpipe’ (ordinary steel tubing). And the superlight 753 was three times stiffer than 531.”

The riders usually found that the “stiffer” bikes made from high-strength tubing performed better. This “confirmed” that stiffer bikes were faster:

1) Observation 1 (builders): high-strength tubing = stiffer frame

2) Observation 2 (riders): high-strength tubing = better performance

3) Conclusion: stiffer frame = better performance

However, Observation 1 is incorrect: The builders mistook yield strength for stiffness.

- Yield strength determines how far you have to bend a frame until it no longer springs back, but “takes a set.” High-strength tubing has a higher yield strength.

- Stiffness determines how much force is required to flex a frame a certain distance. All steels have roughly the same stiffness (modulus of elasticity). The only reason the high-strength frame is harder to bend is that you have to flex it further until you reach the yield point, where it does not spring back any longer.

Even though the high-strength tubing didn’t make the frames stiffer, the higher performance was no fluke. For most riders, a Reynolds 531 frame performed better than a “drainpipe” frame, and a Reynolds 753 frame performed better yet. The observation was correct, even though the explanation was incorrect.

For riders and builders, it didn’t matter that their “stiffer” frames in reality were more flexible (because the tubing walls were thinner), as long as they performed better. All was well for decades: Builders knew how to make well-performing frames, and riders loved riding them. Whether they really were stiff or not didn’t matter.

Things changed when new materials became more prominent during the 1980s: aluminum, titanium and carbon fiber. At first, most bikes made from these new materials were not very stiff, but they were very light. Many riders liked them.

How could the makers of steel bicycles counter the new competition? It was hard to compete on weight, so they focused on stiffness instead. To make a stiffer bike without a huge weight penalty, you increase the diameter of the tubes, and you get a great increase in stiffness with only a small increase in weight. That is how oversize steel tubing became popular.

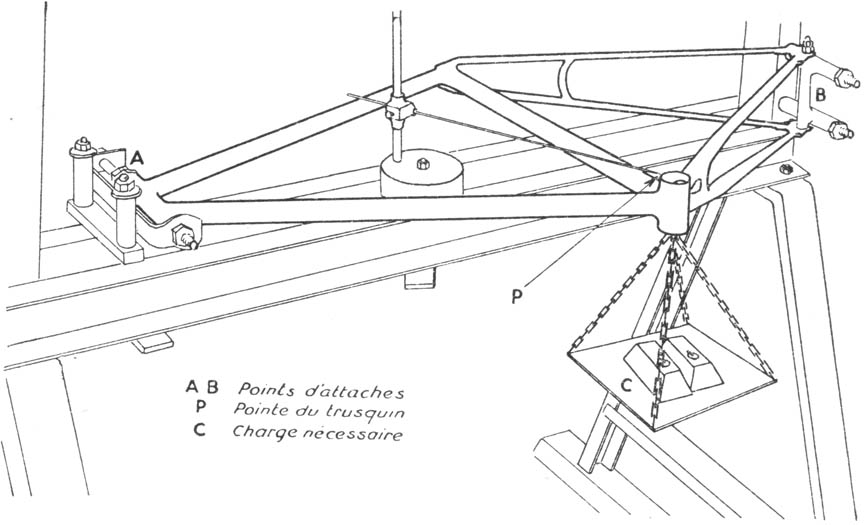

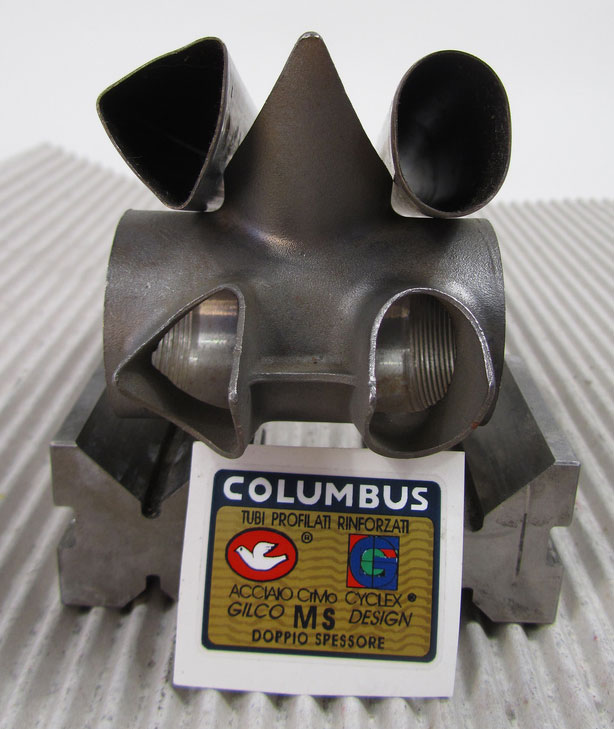

Some makers also offered tubes in all kinds of shapes for improved stiffness in certain directions (above). There were even spiral-shaped reinforcements inside the tubes to increase stiffness (below).

It is ironic that by making their bikes stiffer, the makers of steel bikes may have hastened their demise. (In effect, they killed the cats instead of going after the rats and their fleas.) Instead of making their bikes perform better, they actually returned to the ride characteristics and performance of stiff frames from the early days of cycling.

The makers of aluminum bikes could make their bikes even stiffer, because aluminum’s lower density makes super-large tubing diameters possible with very little weight penalty. (In the medieval analogy, the aluminum bike makers invented a more efficient way of killing cats.) Their bikes also fell by the wayside. (Even Cannondale, the pioneer of oversized aluminum tubing, now uses carbon fiber for their top-of-the-line models.)

Carbon fiber and titanium became the preferred materials for high-end bikes. Ironically, the last steel bikes ridden by top-level amateur racers were made from the superlight (and super-flexible) Reynolds 753 tubing. I remember seeing them under riders whose sponsors would have loved to give them a new bike…

In recent years, it has become clear that many riders perform better on flexible frames, apparently because it allows them to apply their power more efficiently. Many riders and builders extol the virtues of a “lively” frame made from flexible tubing. When we tested different frame tubing in a double-blind test (Bicycle Quarterly Vol. 6, No. 4), we found that two of three riders preferred the most flexible frame both for constant efforts and for all-out sprints. (The third rider could not tell the – very small – differences between the frames in our test.)

Of course, the real story is more complex. There is more to bicycle performance than overall frame stiffness. Frames can be too flexible for a given rider and application. Some riders may even prefer very stiff frames. However, it is clear that the old mantra of stiffer = more performance is not true for most riders.

The main conclusion for me is: False explanations of real phenomena may work for a while, but eventually they will lead you down the wrong path. Whether it’s trying to combat the plague or producing bicycle frames with better performance, we need to examine the real explanations beyond the current beliefs. That is why Bicycle Quarterly does fundamental research to determine what really makes a bicycle perform, rather than just try and figure out how to make bikes stiffer.

If you’re curious about how bikes work, you’ll enjoy our book The All-Road Bike Revolution. In easy-to-understand terms, the book explains frame stiffness, aerodynamics, tires, geometry, how your power output determines your position on the bike, and much more.