ENVE approves Orondo Grade

We developed the 700C x 31 mm Orondo Grade tires for riders like Ted King and Brennan Wertz, who had grown to love supple Rene Herse tires on their gravel and all-road bikes, and now wanted to experience the same comfort and speed on their road bikes. And they wanted a tubeless tire.

What sounded like an easy ask turned into several years of R&D. Of course, tubeless road tires already existed, but none offered the supple ride that Rene Herse tires are famous for. Narrow road tires run at higher pressures, and that tends to force air and sealant through a thin-and-supple casing. That’s one reason why most Rene Herse tires are limited to 60 psi (4.2 bar) when mounted tubeless.

Of course, 60 psi is plenty when you’re running wide tires. With (relatively) narrow racing tires, 60 psi works for flyweight racers like Tadej Pogačar, but neither Ted and Brennan nor most of our customers fit that profile. They need more air in their tires, and that’s the challenge.

To make a thin and supple casing air-proof at high pressure, you need a liner. But most liners make the tire stiffer and harsher-riding—not what we wanted. We tested one material after another—on the road and in the lab—to develop a liner that makes the tire airtight without changing its speed or feel.

We also changed the bead to a stronger, lighter—and much more expensive—material to withstand high pressures in a tubeless setting. Without a tube to reinforce the rim/tire interface, the tire bead needs to be stiffer. specially on supple tires, where the tire casing itself contributes very little stiffness to the system.

When we introduced the Orondo Grade tires last year, Brennan Wertz (right) immediately rode them onto the podium of the Sea Otter Road Race. Success in racing is one way to measure a tire’s speed and reliability. Another important factor is independent lab testing to confirm our in-house results.

For years, we’ve been working with Enve (and other rim companies) on rim/tire fit. In recent years, Enve’s rims have become the gold standard for tire fit. Enve also does their own testing to approve tires for use on their rims. This program started when there was no ETRTO / ISO tubeless rim standard, and every rim maker had to figure things out on their own. Our gravel tires passed Enve’s test years ago, and now the Orondo Grades have been added to the list of ‘Enve-approved’ tubeless road tires.

From the perspective of the tires, Enve’s test is brutal: They test three samples of each casing—Standard, Extralight, Endurance—for a total of nine tires. The tires are mounted on a rim and inflated to max. pressure—90 psi (6.2 bar) in the case of the Orondos. They measure the stiffness of the bead while applying 2000 Newtons of force, and the stretch of the bead with 250 Newtons. Once those measurements are complete, Enve’s engineers increase the tire pressure incrementally until the tire blows off the rim.

The Orondos passed with flying colors. All nine tires stayed on the rims at pressures of more than 150 psi (10.3 bar). Just as important: The diameter of the tire beads varied by less than 0.1% (0.6 mm) for all nine tires they tested.

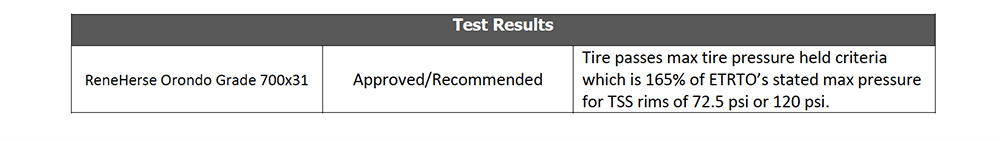

Below is Enve’s test result. As you can see, 120 psi would be sufficient to pass the test, but the Orondo Grades are safe to much higher pressures.

It’s nice to see that Enve’s testing confirms what we’ve found in-house—the Orondo Grades are extremely consistent in their dimensions, and are safe at high pressures with a generous margin of safety.

Ever since we introduced the Orondo Grades, they’ve been among our best-selling tires. They’ve also rekindled my very personal love for road bikes (above). But that’s a story for another day.

More information:

- Rene Herse tires

- Why do today’s pro racers run such wide tires—28, 30 or even 31 mm? Our book The All-Road Bike Revolution explains the science in a fun, easy-to-understand format.