FMB Tubulars

Over the last year, we’ve worked on re-introducing FMB tubulars to the North American market. FMB tubulars perfectly complement our Rene Herse clinchers. They feature similar no-nonsense tread patterns for road, dirt and mud. FMB’s three casings all offer supple performance, but they vary in their degrees of sidewall protection.

If you’ve watched the Spring Classics, you’ve seen FMB tubulars in action. These are the tires that professional racers buy with their own money for races that really count. Races where the best tires can make the difference between winning or not finishing at all.

I met François Marie, the owner of FMB (François Marie Boyaux), many years ago. We did a feature for Bicycle Quarterly on his small shop in Brittany, where he and his small team make the world’s best tubular tires by hand, one by one.

François explained how the tire tread is glued onto the inflated casing, so there are no inbuilt stresses. Most hand-made tubular tires are glued on a flat table. When a ‘flat-glued’ tire is inflated, the tread is stretched into the convex shape. And when the tire deforms as it rolls over the surface, the tread wants to resume its original, flat shape. Stretching it back into the convex shape with each wheel revolution takes extra energy.

As part of Bicycle Quarterly’s tire tests, we tested the performance of two otherwise identical hand-made tires: one with the tread glued to the inflated casing; the other flat-glued. The tire that had its tread glued to the inflated casing – like FMB’s tubulars – was significantly faster.

Why aren’t all tubulars glued on an inflated casing?

First, you need a large number of wheels – one for each tire that is in production at a given time. So this technique can be used only for small-scale production.

Second, you can push down only so much on the inflated casing, and the glue bond requires optimum conditions to be durable. This is fine in Brittany, where it’s rarely hot and humid – but this technique does not work well for making tubulars in tropical southeast Asia. When the production of most hand-made tires moved away from Europe, treads started to separate from the tires, and makers switched to ‘flat-glued’ construction.

As an aside, Rene Herse tires (and most other clinchers) are made in large tire molds, so their tread also naturally assumes its final, convex shape.

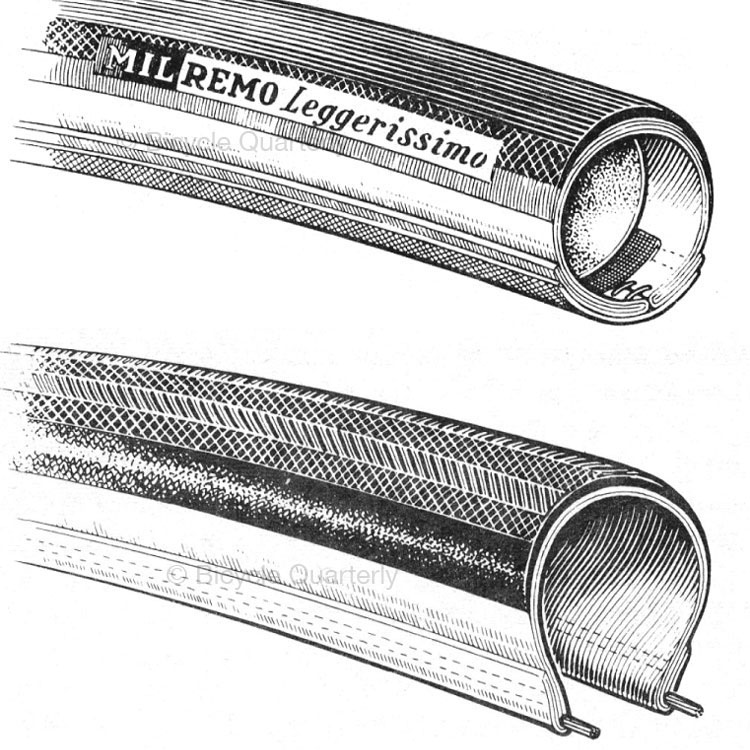

Why tubular tires? A tubular (top) has a round casing, so it can deform around most of its circumference. A clincher (bottom) is constrained by the rim on one side, so it’ll deform only on three sides. So for a tire of a given size, the tubular is more supple, more comfortable and faster on rough surfaces.

My FMB tubulars are one big reason why I love cyclocross. The feel of relatively narrow and yet incredibly supple tires rolling over soft surfaces is intoxicating. There is little that compares to it.

On the road, tubular tires transform a narrow-tire racing bike: Gone is the chatter that you get with narrow clinchers, replaced by supple comfort and supreme grip. That’s why professional racers have used supple tubular tires for almost a century now. And it’s no secret that for special races, professionals mount FMB tubulars, even though they have to pay for them. (FMB puts their sponsor’s logo on the sidewalls.)

A second advantage of tubulars is their resistance to pinch flats, because tubular rims have a flat profile that distributes the load and doesn’t easily pinch (or cut) the tire. Tubeless technology has allowed clinchers to catch up somewhat here, which is why tubulars aren’t an absolute necessity for tough races any longer.

FMB tubulars come with three casings. Their standard casing is made from cotton. It offers superb all-round performance. The silk casing (above) is the ultimate you can find in tubulars, both in performance and supple comfort. And the reinforced, green PRO casing is intended for extra-tough conditions.

FMB tires haven’t been available in North America for a while. Now we are excited to announce that Rene Herse Cycles is now the exclusive North American distributor for FMB tubulars. We have a large selection in stock, from the ultra-light 23 mm Performance TT (280 g) to the 30 mm-wide Paris-Roubaix that has been ridden to countless victories on the cobblestones of the Spring Classics.

We also offer FMB’s fabled cyclocross tubulars. There is the Sprint 2 with its minimalist tread pattern for optimum speed on dry courses…

The Grippo Speed has a more pronounced knobs for added traction.

The Slalom’s elongated knobs are said to offer superb cornering grip. The green tire you see above has the reinforced PRO casing – designed for races and rides where the more supple cotton or silk casings might suffer from sidewall cuts.

And finally, there is the venerable Super Mud. It’s my favorite FMB tire: The small knobs grip tenaciously in mud, and the large open spaces in between prevent the tread from clogging up.

All FMB tires are made to order, and we’ve even asked for a few silk Super Muds. I can’t wait to ride a set on my Alan cyclocross bike – my original (cotton) Super Muds finally have reached the end of their life after 7 seasons of racing. Yes, you read that right – seven years! My FMB tires have proven surprisingly durable (and 100% flat-free), but I have to admit that I rarely have time to race a full season.

Even though the UCI limits cyclocross tires to 33 mm, FMB makes 34s for those renegades who aren’t limited by UCI rules, and who want a little extra air volume. Much wider than that does not make sense with tubulars: A wide tires has so much casing that the clincher rim no longer makes up a significant portion of the tire’s circumference. And that means that with truly wide tires, the advantages of tubulars disappear. But for narrow tires, a great tubular will transform your bike.

We’ve got twenty-one models of FMB tires in stock, in limited quantities.