Introducing the Ultimate Headset

We’re introducing the Rene Herse Ultimate headset to complete our program. Some readers may wonder: Why would anybody run a 1″ threaded headset in this day and age? There’s no doubt that carbon forks need massive tapered steerer tubes—that’s how makers have finally eliminated the dreaded brake judder of earlier carbon bikes with disc brakes. (At least for the most part.) For steel bikes, threaded 1″ headsets remain the best option.

Isn’t it madness to put so much effort into refining components for steel bikes, a technology that many consider obsolete? On the contrary, we feel that the potential of lightweight steel is often underestimated.

Consider that the most sophisticated off-road racing trucks use frames built from CrMo steel tubing. That tubing is very similar to the tubing for steel bikes—just scaled up for these 2-ton monsters. Even though they continue to be built from steel, ‘Trophy Trucks’ have evolved a lot in recent years. Their engines have become more powerful: upward of 1,000 horsepower. Apart from that, most of the development has been in tires and suspension. That’s where the real speed gains come from in desert racing.

That sounds a lot like bicycle racing on gravel: Pro racers have entered the sport and upped the horsepower. And tires have been the biggest tech development. Paralleling those Trophy Trucks, suspension probably has a lot of potential for future development on gravel bikes, too.

There are many reasons why high-performance bikes have moved to carbon, but steel remains a viable alternative. Those Trophy Trucks could also be made from carbon, but steel is easier to customize. The performance benefits of carbon are so small that they aren’t worth the price when it comes to making just a handful of trucks—or bikes—to a specific design. Modern carbon bikes are amazing, but steel can work just as well—if we keep developing and refining these bikes to their fullest performance potential.

That is the reason we’ve developed these headsets (and many other parts in the Rene Herse program): We need them for the bikes we ride and race in Paris-Brest-Paris, Unbound XL, Arkansas High Country Race, and Dark Divide 300. Our approach to these events might be considered unconventional. But then, a decade ago you would have said the same about the wide-and-supple tires that we were championing long before others jumped on the bandwagon.

Why not run threadless headsets on our bikes? Threadless headsets tend to loosen under repeated hard braking. The only thing that holds the adjustment is the stem that’s clamped onto the steerer, and that tends to move if large forces and vibrations combine. (Especially if you tighten the clamp bolts to the very low torque specs that many stem makers recommend.) Stem slippage is enough of a problem that Chris King has developed the GripNut system to help solve this issue.

With a threaded headset, you have a locknut that keeps everything tight. No matter how hard you brake, or how fast you ride over rough terrain, the headset won’t go out of adjustment. As to the 1″ diameter, that’s the perfect size for steel forks. Anything larger just adds unnecessary weight.

However, 1″ headsets aren’t without issues. The bearings are the relatively small and tend to wear, causing the headset to ‘index.’ That’s really distracting or even dangerous, since smooth steering inputs are essential for balancing the bike. Another concern: The front ends of classic steel bikes can shimmy.

Needle bearings are a solution for both these problems. The larger bearing surfaces of the little cylinders (compared to balls) spread the loads over a much greater surface area. The bearings self-align, which compensates for small inaccuracies in the facing of the steerer tube. As a result, needle bearing headsets simply don’t wear out. The bike I raced for a decade has an old Stronglight headset I bought second-hand. After more than 100,000 km (65,000 miles), it’s still turning smoothly.

The needle bearings have an added benefit: There’s a fraction more resistance. Not so much that you feel it when riding, but just enough to dampen oscillations that lead to shimmy. Conversely, free-spinning cartridge bearing headsets increase any bike’s propensity to shimmy, especially once bearings and seals loosen up with use. We’ve ‘cured’ shimmy on many bikes by installing a needle-bearing headset.

Like so many parts designed for steel bikes, most needle-bearing headsets were discontinued long ago. Finding good ones has become nearly impossible, even used, and so we’ve developed our own. In fact, we’ve developed three headsets with needle bearings.

The Low-Stack headset is intended as a replacement for worn headsets of classic steel bikes with short steerer tubes. With a stack height of just 38 mm, it fits on most bikes. It’s very similar to those old Stronglights that I’ve used for so many years.

The new Ultimate headset uses inverted bearings at the top for perfect bearing alignment at all times, even under hard braking. That makes it the perfect headset for a new custom steel bike, or any classic bike that has a long-enough steerer tube.

The Ultimate Rinko headset has retaining rings that keep the bearings inside the cups when the fork is removed from the frame. This is perfect for travel: You don’t want to deal with greasy bearings when you pack your bike.

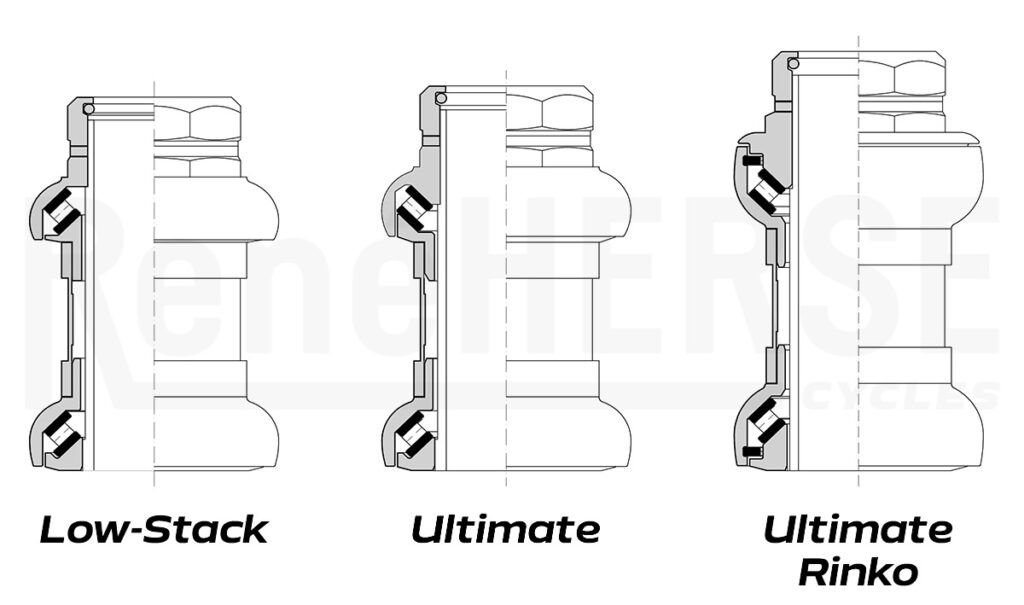

The drawings above illustrate the bearing orientations.

- Low Stack: The lower and upper bearings are oriented the same way to keep the stack height low.

- Ultimate: Inverted top bearings to keep everything perfectly aligned at all times.

- Ultimate Rinko: The upper cup is inverted (like the bearings inside), so the bearings stays inside when the fork is removed. Retaining rings hold the bearings in place.

All Rene Herse headsets use a standard locknut, so you can run headset spacers and/or cable hangers. The parts are polished, not anodized, so they conduct electricity. That’s important if you want to use your frame and fork as the return path for your taillight current.

We also offer the bearings separately. Not because they’ll wear out—they won’t—but in case you lose one, or for some other reason need a replacement. Most of all, offering spare parts is just standard practice for Rene Herse Cycles.

Classic threaded headsets have two other (minor) drawbacks. The first is that the tools to adjust them tend to be big and heavy—the wrenches have to go over the 32 mm locknut. We’ve solved that with our Rinko Headset Wrench, which slips over the locknut, eliminating most of the material. It weighs just 14 grams, and you could take it on every ride. (For which there is no need, unless you end your ride at a train or bus station and need to Rinko your bike.)

The second issue is the little washer that goes between the upper cup and the locknut. It’s an essential part to keep the upper cup and the locknut from turning both together—which would cause the headset to loosen over time. That’s why that washer has a tab—to keep it from turning. A matching groove is cut into the steerer tube. That may work in theory, but in real life, it often causes problems: When adjusting the headset, the washer often turns with the locknut and that tab messes up the steerer tube threads. No so good. And once the tab is messed up, it also no longer keeps the headset from going out of adjustment.

The solution is to put a flat surface at the back of the steerer tube. French bikes were made that way. The thin washer could still suffer—the steerer threads simply cut into it, and then it would turn, too. That’s why we made a thick spacer with flat surface to increase the resistance to turning. That has solved all these issues.

Rene Herse headsets come with conventional washers with a tab, so you can install them on any bike without modification. We offer the flat-backed spacers separately, if you want to use that system.

It’s easy to convert bikes to this system: Simply file a flat section onto back of the steerer. Use the headset spacer as a guide: Keep filing until the spacer fits over the steerer tube. You’re not weakening the steerer, since the flat doesn’t go deeper into the steerer than the groove that was already there. The flat spacer can be used with all 1″ headsets, and it’s an inexpensive retrofit to keep your headset tight.

With this system, you need only a single headset wrench, as the upper cup doesn’t turn when you tighten the locknut. This makes headset adjustment much simpler: Tighten the upper cup, slip on the washer, then tighten the locknut. You’ll need a few tries until you get the preload just right—simply turn the upper cup one way or the other until the pre-load is right after you tighten the locknut.

There’s none of the frustration you get when adjusting a headset with two wrenches: Since both sides turn and that tabbed washer often doesn’t stay put, you often have to keep trying until you arrive at the perfect adjustment by pure chance.

With the flat spacer, there’s no need to use brute force on the locknut. Just tighten the Rinko headset tool firmly by hand, and the headset will stay put, no matter how harsh the terrain. If you want to add some extra security, insert an 8 mm Allen wrench into the socket for added leverage. I do that before big races and adventures into remote places, for added piece of mind.

When we head to races like Unbound XL, it’s good to know that we can rely on our bikes 100%, and that their performance has been optimized to the nth degree. That way, we can focus on enjoying the ride, without thinking about our bikes.

More information:

- Rene Herse headsets

- A steel bike lighter than carbon? The story of my Rene Herse for Unbound XL.

Photo credits: SPEED | Robby Gordon Off-Road (Trophy Truck); Marc Arjol Rodriguez / Velophoto.tx (Unbound XL action)