Nivex Derailleurs Have Arrived!

Nivex derailleurs and most associated parts are now in stock! It’s been a long journey, with R&D starting more than four years ago. When you make a derailleur that’s not just a copy of what’s already out there, but fundamentally different, you’re starting almost from zero. (The 1930s Nivex provided a wonderful inspiration, but it was never intended for modern drivetrains.) It’s been exciting and fun, frustrating at times, and ultimately very rewarding, and now we’re excited to share the fruits of our work.

Why would anybody create a new derailleur, when there are already many out there that work very well? The answer is simple: Because we want a different derailleur. For lack of a better word, modern derailleurs are digital: You push a button, and they shift. That’s why the best derailleurs use electric motors, which are more consistent than a human pushing a lever that pulls a cable. Modern electronic derailleurs are very, very good, and yet…

I love analog experiences. When I cook, using a great knife is more fun than just throwing vegetables into a KitchenAid. When I ride my bike, I enjoy feeling the shift happen. I pull the lever and feel the chain mesh with the new cog as a result of my hand movement. It doesn’t make me faster, but it makes riding more fun.

I like analog, but I don’t enjoy sub-par performance. Modern electronic derailleurs have really raised the bar when it comes to shifting performance, and I feel that an analog derailleur should work at least as well, if not better. I want my derailleur to operate with consistency throughout the gear range, for up- and downshifts alike. I want the shifts to happen instantaneously, so that I can let up slightly on the pedals to reduce the chain tension. Then I want to get back on the power immediately, before the bike loses any perceptible speed. All this should happen intuitively. My bike should feel like an extension of my body, not something that requires thought for something as simple as a gear shift.

Riding dozens of different shifting systems over the years—including oddballs like the Retrodirect (pedaling backwards gives you a different gear ratio) and Vélocio’s Bi-Chain (each chain is engaged for a different gear)—has shown me that current derailleur design is just one of many possible solutions to the problem.

What happens if we start from scratch to make the best mechanical derailleur possible? The first thing to go is the return spring. You’ll never get consistent action when a spring is moving the derailleur in one direction, while a cable pulls it in the other. (Retrofriction shift levers are a big improvement, but even they are just a work-around.) With the Nivex’ desmodromic operation, cables pull the derailleur in both directions. This also means much lighter action, since you aren’t fighting a return spring. You get immediate shifts with no lag, since the derailleur is connected to the lever without any slack. Fun fact: Modern electronic derailleurs are desmodromic, too. They use their motors to move the chain in both directions, without a return spring.

The next thing to rethink is the derailleur location. Current derailleur mounts are a legacy from the days when bikes didn’t have derailleurs. The first racing derailleurs were designed as retrofits, and the easiest way to attach a derailleur to the bike was to sandwich a hanger onto the rear axle. The hanger eventually became incorporated into the dropout, but it’s an archaic system with real drawbacks.

To route the derailleur cable over the derailleur, there’s a piece of cable housing, which introduces friction and imprecision into the system. With desmodromic operation, you’d need two pieces of shifter housing—which would negate most of the advantages of eliminating the return spring.

The Nivex is located underneath the chainstay. This allows for open cable to run all the way from the shift lever to the derailleur. Less friction, less flex, more direct action are the result. This also makes the derailleur totally impervious to mud—as I was able to confirm during this year’s incredibly muddy Unbound XL 350-mile race.

The under-chainstay location tucks the derailleur out of the way, so it’s protected from damage. The Nivex doesn’t touch the ground at all when you lay down the bike (or when it falls over). Good-bye to bent derailleur hangers! Since the derailleur is in front of the cassette, rather than underneath, there’s also more ground clearance: useful when riding across rough terrain. And the parallelogram sits further inward, so it’s less likely to get damaged when you ride close to rocks.

Mounting the derailleur under the chainstay has a (small) drawback: It makes wheel removal a bit more difficult. The chain loops around the cassette on three sides. That said, installing the wheel with a Nivex isn’t much more difficult than installing a modern disc wheel with a thru-axle. (Mid-century Nivex derailleurs had a chainrest, which allowed removing the wheel without touching the chain at all, but this feature doesn’t work well with modern cassettes.)

Conventional derailleurs have simple springs, and the chain tension varies significantly as you shift across the gear range. On the small chainring, the tension is so slack that the chain often hits the chainstay when you ride over rough terrain. Many modern ‘gravel’ derailleurs use clutches to prevent this chainslap, but clutches are heavy and not conducive to smooth shifting. The Nivex solves this problem with a smart compensator arm that keeps the spring tension constant as the derailleur cage rotates. This eliminates chainslap on all but the roughest terrain—it’s as good in this respect as modern ‘gravel’ derailleurs. Constant chain tension also means totally consistent shifts, no matter where you are in the gear range.

The Rene Herse Nivex weighs just 176 g, making it one of the lightest derailleurs available today. (Even Campagnolo’s carbon-and-titanium Super Record weighs more.) The shift lever is also very light at 54 g. This ultralight weight is the result of smart design, not because we use ‘stupid-light’ parts like tiny aluminum screws to pinch the cables. Everything on the Nivex is properly dimensioned, and you don’t need a torque wrench to install and adjust it.

The shift lever mounts on a standard shifter boss. The Nivex is a modular system that works with cassettes from 6 to 12 speeds. To start, we offer an indexed 11-speed shift lever (for Shimano cassettes). Shift levers for friction, as well as 7-, 8-, 10- and 12-speed are on the way. The indexing is softer than on most other shift levers. The notches serve as a guide for the lever, but they don’t take away the analog feel. Since the Nivex has no return spring, there’s no need to have very strong notches. (With conventional derailleurs, the notches prevent auto-shifting as the frame flexes.)

In the course of our R&D, we’ve learned one thing: You can’t optimize shifting unless you design the derailleur for a specific gear range. (SRAM came to the same conclusion with their latest XPLR—the only derailleur that shifts as fast as the Nivex.) The 11-speed Nivex is optimized for 11-30 cassettes. (You can also run 12-30 or 11-28.) Larger cogs would require an extra articulation, adding weight and complexity (and reducing ground clearance). With modern sub-compact cranks, a 30-tooth large cog is sufficient for most riders and most terrain.

We’ve developed cable tensioners that make setup much easier, especially when running the Nivex indexed. The system also includes a braze-on for the chainstay, to mount the derailleur. (You can retrofit the Nivex on existing frames.) A special rear dropout is on the way: It opens slightly to the rear, making wheel removal much easier, especially on bikes with fenders. A matching left shift lever to operate your front derailleur is in development.

The Nivex derailleur isn’t a prototype or a first iteration that will be replaced by a ‘new-and-improved’ model in a year or two: The system has been tested over 10,000s of miles, including Paris-Brest-Paris, the Oregon Outback and Unbound XL (above). This is the final version, it won’t change anytime soon, and I’m confident that it’s more reliable than any derailleur you can buy today.

The Nivex has been designed for durability. The arms of the parallelogram articulate on bronze bushings that move with silky smoothness and offer remarkable resistance to wear. And thanks to the smooth desmodromic actuation, the shifter cables last practically forever. If you need to replace one, it’s a standard shifter cable (extra-long version for tandems and triplets). The pulleys use standard bearings. (We have cables and pulleys in stock.)

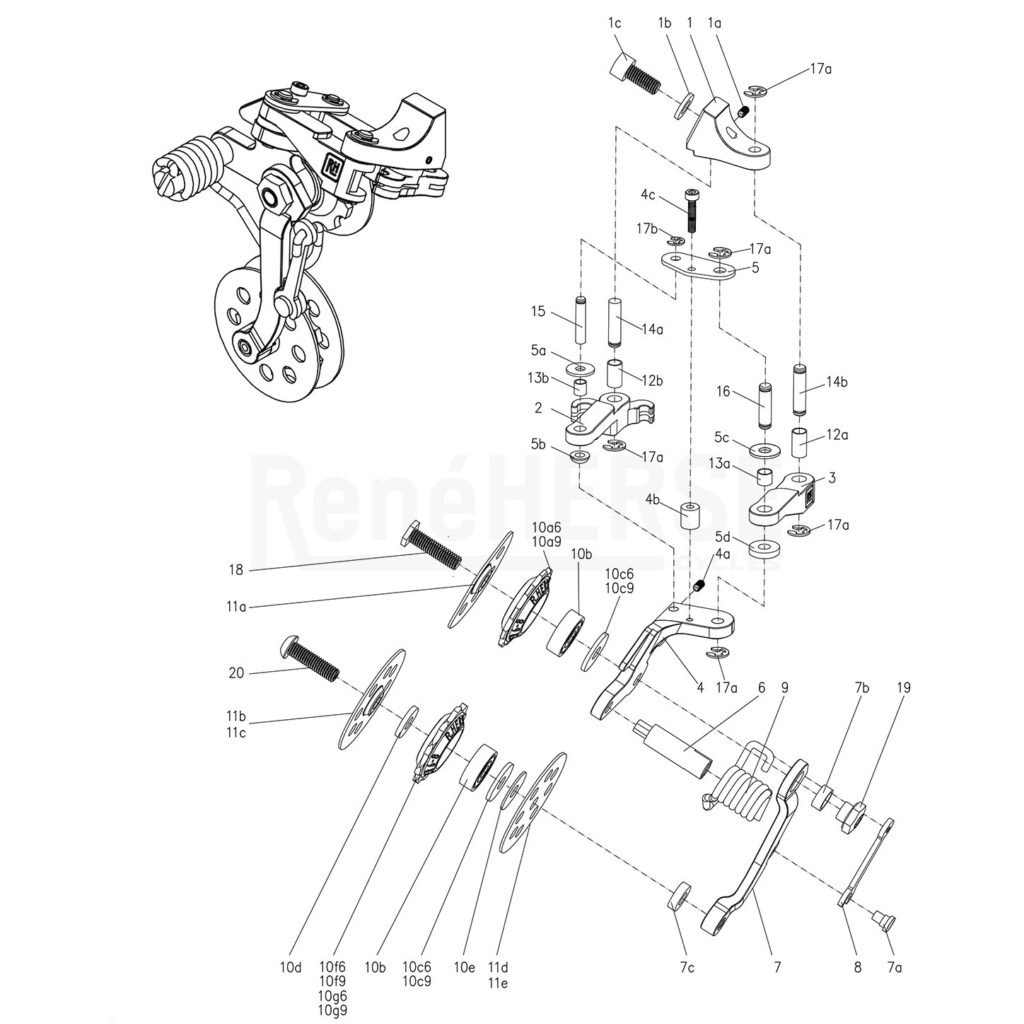

The Nivex derailleur and its shift lever are completely rebuildable. Parts are available from the get-go, which is something often overlooked with ‘rebuildable’ components. (It doesn’t help if you can disassemble a component, if spare parts aren’t available.)

Of course, all that R&D and technology do not come cheap. Derailleurs are incredibly complex: The Nivex consists of more than 50 custom-made parts. Nivex derailleurs and shift levers are made by hand in small batches. And yet our Nivex derailleur costs no more than other top-of-the-line derailleurs.

We are under no illusion that the Nivex will take over the cycling world. The idea is that if you’re building a no-holds-barred custom bike, there’s now an alternative for riders who are looking for an analog shifting experience that you simply can’t find anywhere else.

The Nivex is not intended for everybody, nor for all terrains—in really rough terrain, electronic shifters are hard to beat—but on 98% of my rides, the Nivex puts a smile on my face. During the Oregon Outback FKT ride last year, I was pedaling through the Ochoco Mountains under a full moon. The terrain is relentlessly up and down, so the Nivex of my bike got a real workout. After 15 hours of riding non-stop, the bike felt like an extension of my body. I didn’t even think about changing gears, and the individual shifts barely registered, yet they contributed to the fun of riding the bike. It’s a feeling that’s hard to describe, but easy to remember.

Further Reading:

- Derailleurs and parts in the Rene Herse program

Nivex® is a registered trademark of Rene Herse Cycles.