The Missing Link: Suspension Losses

A ‘wide tire revolution’ has swept through the cycling world. Whether it’s gravel racers on 48 mm rubber or Tour de France champions on 30s, today’s tires are wider than ever before. At the same time, pressures have dropped. In the past, 4 bar (58 psi) would have been a sign that the tire was losing air and almost flat—time for an urgent wheel change. Today that’s the pressure Tadej Pogačar runs on the road.

After years of resistance, the idea that wide tires can be fast has been widely accepted, yet the underlying science remains relatively unknown. Many cyclists have heard that vibrations slow down the bike, but how does this work? Where does the energy go?

Suspension losses occur when vibrations cause friction. This friction turns energy into heat, and that energy is then no longer available to power the bike forward. Suspension losses explain how vibrations slow the bike down, and that is where the speed of wide tires comes from: They reduce vibrations.

This is the story how suspension losses were discovered as an important factor for cycling speed. This research led directly to our supple Rene Herse tires. However, the findings are applicable to all tires and to bicycles in general.

On a bicycle, suspension losses occur mostly in the rider. What we feel as discomfort when we ride over rough surfaces and our bikes vibrate, is friction created by our body tissues as they rub against one another. Body tissues are ‘jiggly’ and can absorb a lot of energy. By comparison, the suspension losses in the bike’s frame and components are relatively small.

Suspension losses don’t just occur in bikes. In cars, suspension losses heat up the shock absorbers: During my childhood travels with my family in Africa, the shock absorbers of our VW Beetle caught on fire on washboard gravel roads—one after another, until they were replaced with heavy-duty shocks.

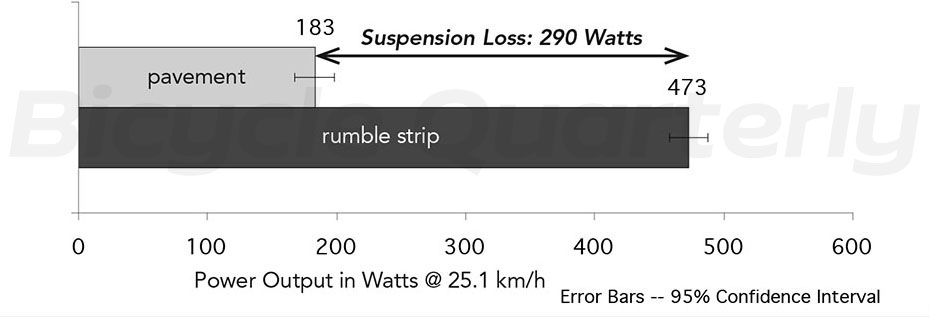

There is no danger that cyclists will burst into flames, but the energy lost as the bike vibrates can be significant. We once measured it at 290 watts. That is a huge power loss. It’s the reason why wider tires at lower pressure are actually faster on rough roads.

Even on smooth roads, suspension losses are significant. The Tour de France goes over some of the smoothest roads in the world, and yet Pogačar and the rest of the peloton have adopted wide tires. Wide tires offer many advantages—better traction, more comfort, fewer punctures—but the pros care about speed first and foremost: Wide tires cannot be slower than narrow ones, otherwise the pro peloton would not have adopted them. And yet its seems that many racers aren’t sure why wide tires roll fast.

“Very interesting stuff. Certainly not the normal thinking of most minds out there right now—namely the friction of body tissue during a ride.” That’s how a professional gravel racer summarized the thinking in the peloton earlier this year, when I mentioned suspension losses. And yet the idea is nothing new. It just hadn’t been applied to cycling.

Back in 2006, when we started testing the performance of tires for Bicycle Quarterly, it was universally accepted that higher pressures rolled faster. For road races, I and the rest of the peloton ran 20 or 21.5 mm tires. We inflated them to 9 bar (130 psi) or more. We thought that the only thing that mattered were hysteretic losses that occur when the tire flexes as it touches the road. Making the tire flex less reduces these hysteretic losses—hence high pressure was thought to be faster. Cycling expert Jobst Brandt summed up the thinking at the time: “At infinite pressure, only the thin band of tread rubber flexes, and rolling resistance is approaching zero.”

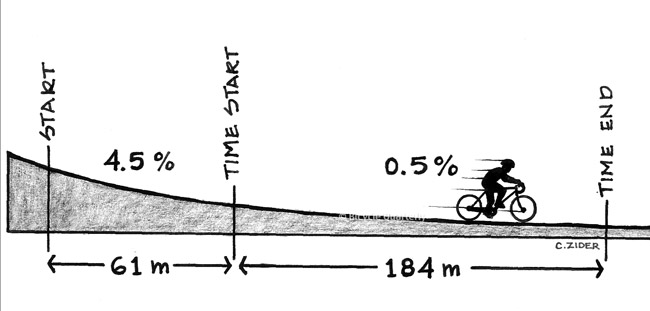

Our tire tests were different from others: We measured tire performance with a rider on the bike. Rather than test just a tire and wheel on a drum in the lab, we rolled a bike down a carefully chosen hill and measured its speed over a set distance. We made sure there was absolutely no wind, that temperatures were constant, and that the rider’s position did not change. We repeated tests of the same tires periodically during our testing. We also conducted a rigorous statistical analysis. Together, that gave us a good idea how accurate our testing was: We could detect small differences in tire performance using this method.

To our and everybody else’s surprise, we found that high tire pressures didn’t make our test bike faster. In fact, tires rolled at roughly the same speed, no matter the pressure. (Until pressures got so low that the bike was difficult to control.)

At first, we thought there was an error in our testing. We tested different tires, time and again, and always found the same: Higher pressures didn’t make tires faster, at least for high-performance tires. To check our results again, we went to an outdoor track and tested with a power meter (above). Even with this completely different methodology, we found that high pressures did not roll faster.

How could we explain this? Enter Jim Papadopoulos, one of the foremost cycling tech experts of all time. He had written a chapter for the book Bicycling Science, where he mentioned a 1960s U.S. Army study of vibrating tank seats. The Army found that, when a human sat in the vibrating seat, their body would absorb energy due to internal friction of their body tissues—what they called ‘suspension losses.’ They found that human bodies could absorb up to 2,000 watts before the tests became too painful to continue. The level of discomfort was directly related to the amount of energy their bodies absorbed. “2,000 watts!” I exclaimed when I read this. That’s more than the max power of most pro cyclists!

It seemed likely that the same suspension losses occurred in cyclists’ bodies. While the tires themselves absorb less energy at higher pressures, the suspension losses in the rider’s body also go up. The two effects cancel each other out. Higher pressures simply move the energy loss from tire to rider. We realized that, given a choice, we’d rather have our tires take the stress than our bodies. That is how the ‘wide tire revolution’ got started. Rather than just look at the energy loss within the tire itself, tire design also should minimize vibrations and suspension losses. That was the blueprint for our Rene Herse tires—what made them different from other tires at the time.

First we had to confirm our hypothesis. How could we show that suspension losses were the reason why high tire pressure offered no benefits? How could we measure suspension losses? We thought about using a thermal camera and measuring the heat generated in the rider’s body. We rejected this idea as impractical and not accurate enough. How about riding on a smooth road and on a rough road, and comparing the power required for each? The difference would show us the additional suspension losses on the rough surface. For tight control of all variables, we needed these two surfaces to be next to each other, so we could do repeat runs, alternating between the smooth and rough surfaces.

That’s when I remembered the rumble strips that were cropping up on highways all over the state. Regular grooves were cut into the smooth road surface at the edge of the traffic lanes. If a driver dozed off behind the wheel and drifted off the road, the rumble strips would cause strong vibrations and noise that (hopefully) would jolt the driver awake. As cyclists, we knew that if we inadvertently got onto these rumble strips, it wasn’t just very uncomfortable, but also slowed down the bike immediately. We thought that it should be possible to measure this energy loss.

These grooves were always the same, unlike a gravel road where we might hit different rocks during each run, and where a smooth track might appear after multiple test runs and skew our results. This consistency makes rumble strips perfect for scientific testing.

Not far from a Seattle, a highway had been widened recently. Brand-new and ultra-smooth asphalt was bordered by rumble strips—perfect for our testing. On a calm Sunday morning, we headed out to test. That was 15 years ago, and the photo above reminds me that helmet design has changed since then! (And Bicycle Quarterly was still published in black & white!)

We chose an off-ramp, both for safety and because it had less traffic. (Whenever a car passed, we redid the test run, since the wind caused by the passing car might affect our results.) And then I rode back and forth on the rumble strips and the smooth asphalt, doing repeat runs with each setup we wanted to test. Meanwhile BQ contributor Mark prepared the equipment for each test run. We didn’t just want to confirm our hypothesis, but we also tested whether suspension losses were reduced by wide tires, low pressures, larger wheels, suspension forks, padded bar tape and other components.

The immediate result of our testing was that my body hurt everywhere after riding 15 miles (24 km) on these rumble strips. I could literally feel the friction between my body tissues and the heat that was generated!

When we looked at our data, we found that the suspension losses were huge. Rumble strips are almost a worst-case scenario—they feel similar to cobblestones in Europe—but that was the point. With 26 mm tires at high pressure—the standard racing setup at the time—I needed 290 watts more on the rumble strips than on the smooth asphalt. That’s less than the 2,000 watts the Army found in their tank-seat experiments—probably because my muscles were tensed and didn’t jiggle as much as they would when sitting passively on a seat. But it’s still a lot of extra power the rider has to generate to keep the bike up to speed on the rough surface. In fact, each test run on the rumble strips was an all-out sprint at almost 500 watts, while the next run on the smooth asphalt (at the same speed) provided some welcome rest at about 200 watts.

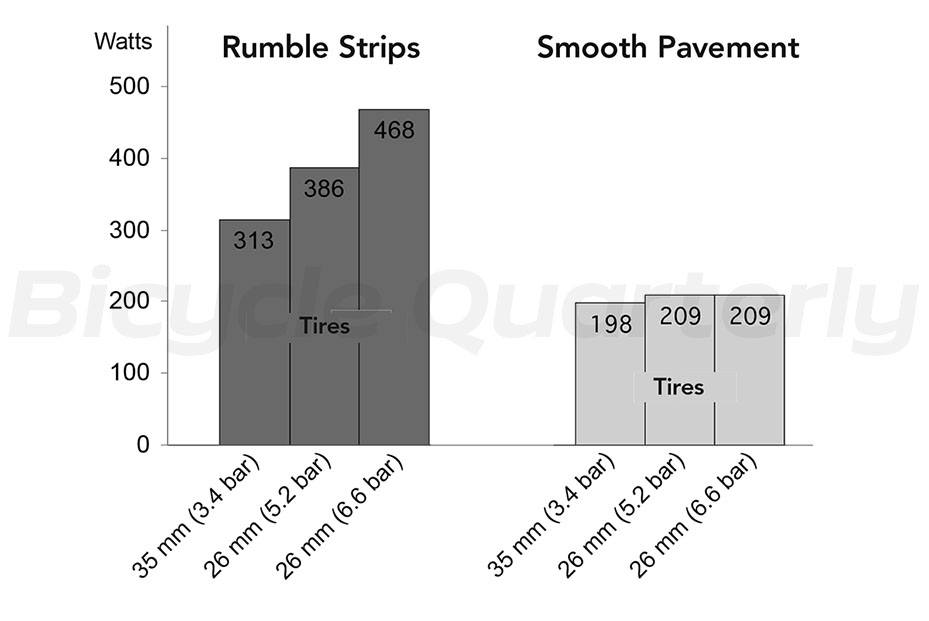

We found that different setups could reduce the suspension losses on the ultra-rough rumble strips. Simply lowering the tire pressure saved 80 watts. Going to wider tires (35 mm) and even lower pressure (3.4 bar / 50 psi) brought another 70 watt improvement. Now the bike required ‘only’ 313 watts instead of 468!

On the smooth asphalt, the wider tires and lower pressure didn’t slow the bike. This confirmed our previous research once again. (The raw data show the 35 mm tires faster on the smooth asphalt, but the difference was not statistically significant—meaning it might just be noise in the data due to slight variations in rider position, etc. All other differences shown above were statistically significant.)

Why didn’t we test tires wider than 35 mm? Remember, this was 2009, when 35 mm tires were incredibly wide for a road bike. Wider tires with supple casings were not even available yet. (Rene Herse introduced them in 2014.) Additional testing since then has shown that tires wider than 35 mm at pressures lower than 50 psi further reduce the suspension losses.

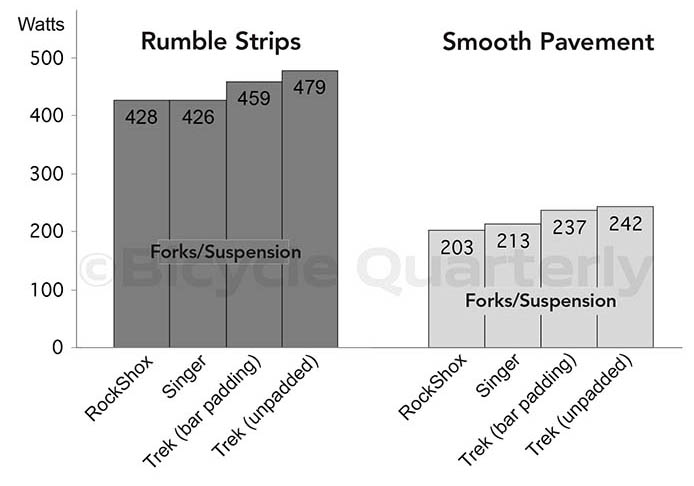

In addition to wider tires and lower pressure, suspension forks also brought a significant reduction in suspension losses. Both telescopic shocks (RockShox) and flexible steel fork blades (Singer) saved about 50 watts (above) compared to a beefy and stiff fork from a mid-priced hybrid bike (Trek). (The padded bar tape did not pass the statistical test, so we don’t know whether it really helped or not.)

In our tests, the only difference between the two surfaces was that one was smooth, the other rough. Both surfaces were right next to each other. Slope, temperature, slight wind (we tested on a perfectly calm day), rider, bike—everything was exactly the same. The only thing that changed was that we alternated between riding on the smooth asphalt and the rumble strips. And the rumble strips required a lot more power because of the vibrations. Just as importantly, reducing the vibrations—with wider tires, lower pressure and/or suspension forks—made the bike more comfortable and significantly faster.

At first, our findings were met with incredulity. “Energy lost in the rider’s body?” It may seem strange that vibrations in the rider’s body slow down the bike, even though nothing inhibits the spinning of the wheels. Until you think about the first law of thermodynamics: Energy cannot be created, nor can it be destroyed. Friction between body tissues turns energy into heat. And that energy has to come from somewhere. Any energy taken from the bike will slow us down.

Pro racers, always on the lookout for more speed, soon took note of our findings and started moving to wider tires. Then others replicated our results and came up with new names. Things like ‘vibration losses’ and ‘impedance’ entered into the conversation. The correct technical term is ‘suspension losses,’ and it makes sense to stick with it: That’s what other fields, like the car industry, use.

Today, wide tires and low pressures are widely accepted. In fact, Tadej Pogačar’s tires measure about 32 mm on the wide rims he’s running. And yet, as my pro racer friend confirmed, it’s not widely understood why we no longer inflate our tires to the max, and why we no longer run narrow tires that have ultra-high pressure ratings.

Understanding suspension losses is essential for selecting our equipment. The take-home message is simple: The rougher the surface, the bigger the gains from reducing suspension losses. How to reduce suspension losses? As the U.S. Army and Bicycle Quarterly’s tests showed, the more uncomfortable your bike, the higher the suspension losses. Rather than ‘tough it out’—for example, by running narrow tires at high pressures—reducing the discomfort from vibrations actually makes you faster.

Suspension losses are what underlies the ‘wide tire revolution,’ and everything that followed. Without this discovery, there would have been no Rene Herse tires. Road cyclists would still be riding pencil-thin tires at rock-hard pressures. ‘Gravel grinders’ (remember that term?) would still discuss whether 25 or 28 mm tires offer the most speed on gravel. That was the state of the art was when we started our research, and it shows how far we’ve come. Today we float over rough gravel and smooth roads alike, at speeds that were unimaginable back then. That’s a true revolution, and it has made cycling not just faster, but also more fun.

More Resources:

- Our research about suspension losses was first published in Bicycle Quarterly 29 (Autumn 2009).

- Make sure to sign up to our newsletter to be the first to learn about bike tech, new products and other goings-on at Rene Herse Cycles. (We won’t share your info, and you can unsubscribe anytime.)

- Want to know more? Our book The All-Road Bike Revolution summarizes all the research that has changed cycling in recent years. Find out why wide tires can be fast, how to find a frame that optimizes your power output, and how to get a bike that handles like an extension of your body. (Also available in German and Japanese.)

Photo credits: Marc Arjol Rodriguez (Velophoto.tx; Unbound racers); Jered Gruber (Tadej Pogačar); all used with permission.