The Science behind Ultra-Wide Rims

When we started riding wide, supple tires more than a decade ago, we wondered about rim width. Do extra-wide tires need extra-wide rims? Figuring this out was part of our research into tire and bicycle performance.

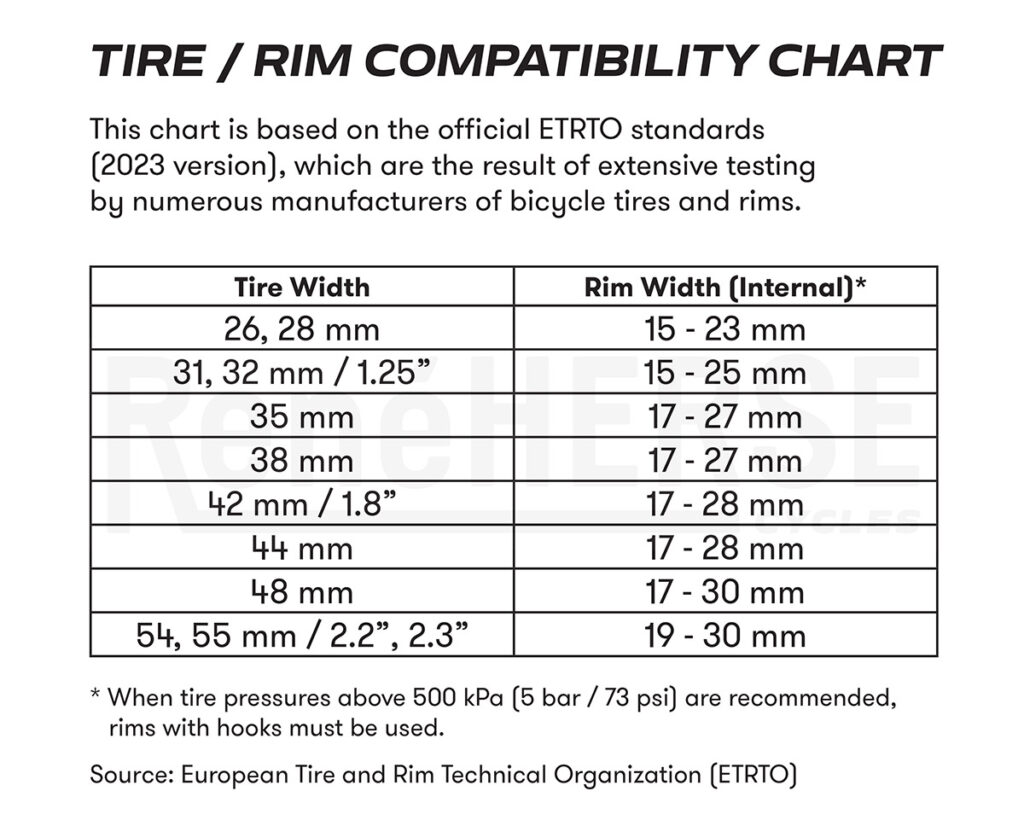

Last week, Zipp introduced their new 303 XPLR gravel wheels. Their main selling point are ultra-wide rims. Their outer width of 40 mm should provide a better match with 40- to 45 mm-wide tires that are popular for gravel racing. According to Zipp, one advantages is better airflow between tire and rim. The tire/rim combo is not shaped like a light bulb, but the tire smoothly transitions to the rim. Lower tire pressure is a second benefit, which, according to Zipp, optimizes speed and traction on rough terrain. A concern with the new rims is their inner width of 32 mm. That’s significantly wider than the 28 mm maximum allowed by ETRTO / ISO standards for 40-45 mm tires. By-passing the standards isn’t a bad thing in itself, but it means that Zipp needs to figure out which tires can be used safely on their new wheels.

This aspect of the new rims reminds us of the controversial crash of Thomas De Gendt in this year’s UAE Tour. De Gendt lost control when his 28 mm tire came off his 25 mm-wide (internal) Zipp rim—a combination that’s also outside the ETRTO / ISO standards. At the time, there was much speculation whether the rim was too wide to support the tire, and whether that caused the tire to blow off. In the end, it appears that the crash was caused by a broken rim. However, running a narrow tire on a wide rim may have been a contributing factor, because it makes the tire more likely to bottom out (see below).

There is a lot to unpack with the new ultra-wide rims, so this may be a good time to revisit our research into how rims and tires interact.

Previous XPLR Wheels

For the last 1.5 years, I’ve been running Zipp 101 XPLR wheels on my OPEN × Rene Herse U.P.P.E.R. Their internal width is 27 mm, and they feature Zipp’s Moto technology: The single-wall rim is supposed “to locally flex and stay parallel to the ground during cornering.” It’s an odd concept for a two-wheeler that leans into corners. I was also worried that all this flexing of the rim would cause the spokes to momentarily losing tension, which would lead to loose spokes and premature breakage. However, photos taken during hard cornering show that, if the rim twists at all, it’s so little that it’s imperceptible.

There were some concerns that a rim this wide would make the tires more square in profile and affect cornering. That hasn’t been an issue for me. Rene Herse tires have a very gradual transition between tread and sidewall, so they always assume their round shape, no matter the rim width. On the road, my tires feel the same on the 27 mm-wide XPLR rims as they do on the 18 mm-wide Stans on my Firefly (internal widths).

The new 303 XPLR wheels are even wider than my 101s, and they ditch the (heavy) single-wall construction in favor of a more conventional aero profile. Let’s look at what this does.

Aero

A year ago, we looked at the aerodynamics of gravel bikes and concluded that aero wheels don’t provide much benefit with wide gravel tires. That’s because the rims are too narrow to provide smooth airflow at the transition from rim to tire—the infamous ‘light bulb’ shape. That was a bit controversial back then. Several rim makers contacted us to protest vehemently, pointing to their computer modeling that showed significant advantages for aero rims with wide gravel tires. Other engineers agreed with our assessment back then—off the record.

Zipp’s marketing material for the new wheels explains that, with current gravel wheels, “aerodynamics are ruined by mismatched rim and tire widths.” The new 40 mm-wide rim (external) provides an almost-perfect match for a 40 mm-wide tire. (A widely stated rule is that the rim should be 105% as wide as the tire, which translates to 42 mm rims with a 40 mm tire.)

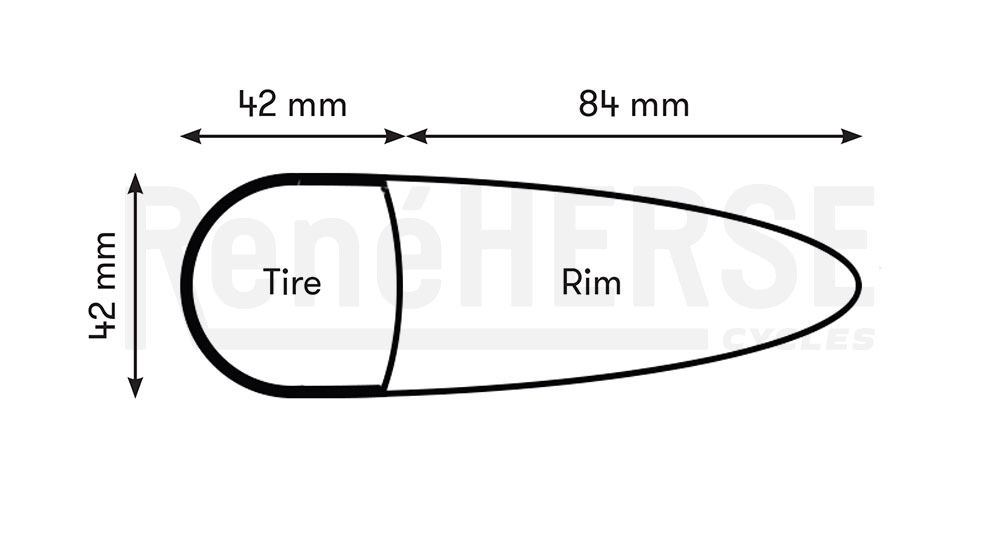

However, as our article last year pointed out, the tire/rim interface is only one of two problems with wide tires on aero wheels. The other is the rim depth. To provide smooth airflow, an aerodynamic teardrop shape should be at least three times as long as it is wide (above). That applies if the shape is in ‘free air.’ If it’s surrounded by other parts that create turbulence (fork blades, spokes, etc.), that ratio is higher, more like 5 : 1. Even a 3 : 1 ratio is not practical with wide tires—you’d end up with ultra-deep rims that are difficult to control in crosswinds.

The rims of the new Zipp 303 XPLR wheels are 54 mm deep. That’s only 29% taller than a 42 mm tire. To put this into perspective, a road rim for a 25 mm tire with the same proportions would be just 32 mm tall. Nobody would consider a 32 mm rim optimized for aerodynamics. Aero-optimized rims for 25 mm tires are 70-80 mm tall. For a 42 mm tire, that translates to a rim depth of 92-101 mm—almost twice as deep as the new 303 XPLR rims.

It’s conceivable that a technological breakthrough could change these rules. In theory, it might be possible to create a shorter shape that keeps the airflow attached to the rim—sort of like the ‘virtual tail’ of some race cars.

That doesn’t appear to be the case here. Zipp claims 2 watts savings at gravel race speeds of 29-36 km/h (18-22 mph). On downhills, at 45 km/h (28 mph), the savings go up to 5 watts. That’s not a lot. For comparison, Zipp claims much greater savings—6.4 watts—for their wing-shaped handlebars. We can argue whether computational fluid dynamics (CFD) are as reliable as actual wind tunnel testing, but one thing is clear: Aero advantages of the new ultra-wide rims are small—even by Zipp’s own estimates.

Another issue are vibrations, which can disrupt the airflow. Perfect airflow in a wind tunnel may not translate into performance gains on real roads, especially on gravel, where the wheel vibrates so much that the air has trouble adhering to the rim. It would be interesting to test a wheel that vibrates in a wind tunnel and compare it to a smoothly spinning wheel…

Low Tire Pressure

More than the aero performance, Zipp stresses another advantage of their ultra-wide rims: They allow you to run lower tire pressures.

All other things being equal, lower tire pressures are faster on rough surfaces. We first showed this when we’ve measured suspension losses and how to reduce them, with our famous tests on rumble strips—which provided a rough surface right next to smooth pavement to allow a direct rough/smooth comparison. That was way back in 2009. It’s nice to see that these results are now accepted in the mainstream.

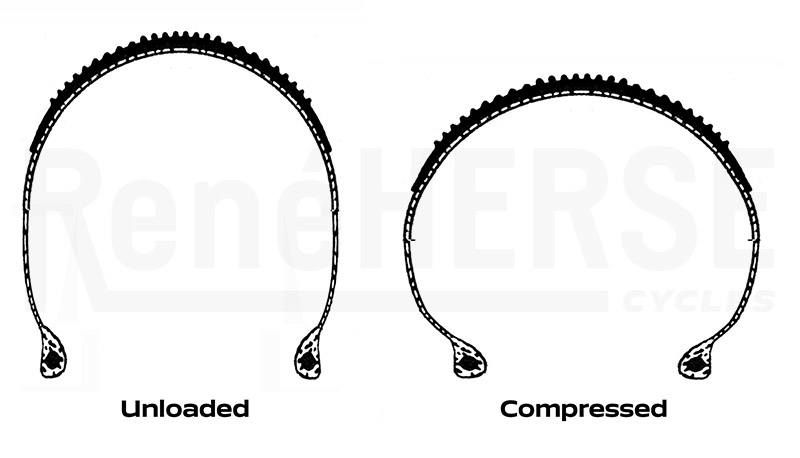

How does rim width factor into this? With a wide rim, the tire is U-shaped, and the sidewalls are close to vertical (left). They help support the weight of bike and rider. With a narrow rim, the tire is O-shaped (right), making it easier to flex, and less able to support the bike’s weight.

Here’s another way to think of it: Tire rubber and air pressure are two springs. To get the overall stiffness, you add the rubber and air springs together. So it’s true: A stiffer tire allows you to run less air.

At this point, it’s important to remember that low pressure is not an end in itself. On rough terrain, lowering you tire pressure makes you faster because softer tires transmit fewer vibrations. Making the tire U-shaped and stiffer changes an important variable: It replaces the air spring with a rubber spring. The overall stiffness of your tire is the same as before. However, replacing air with rubber as a spring is counterproductive: Air compresses with almost no friction, whereas compressing rubber takes a lot of energy. That’s why supple tires are so fast and so comfortable: They use mostly air to support bike/rider, and their casings have very little stiffness, making them easy to compress as the tire deforms when it touches the ground.

Viewed that way, the ultra-wide rim has the net effect of making the tire less supple. While that allows you to run lower pressures, it does not make the tire faster. Otherwise, airless tires—which run at zero pressure—would be the fastest tires of all. In fact, they are the slowest, because flexing all that rubber with every wheel revolution takes a lot of energy.

Regressive Spring

A number of independent tests of the 303 XPLR wheels mention that tires bottom out more often with the new rims. (Examples include reviews by Dave Rome on the Escape Collective on the Escape Collective and by Jordan Villella on BikeRadar.) Here is why that tends to happen with ultra-wide rims:

Remember the two springs that support bike and rider? One is the tire, made of rubber. The other is the air inside the tire. With a U-shaped tire, you’re using the rubber spring for a significant portion of the load (left). However, when you hit a bump, the tire flexes and becomes more O-shaped (right). As the sidewalls bow outward, they lose much of their stiffness. Now air pressure is all that’s left supporting bike/rider. But we’re running less pressure—that was the point of the ultra-wide rims. With the tire stiffness going down, that low pressure is not enough to support bike and rider. This means the tire will flex more, making it even less stiff. And so on… until the tire collapses, and you bottom out on the rim.

Compare that to a narrower rim and a tire inflated to higher pressure. At the start, the overall stiffness is the same as with an ultra-wide rim and lower tire pressure. As the tire flexes, tire pressure doesn’t change. (In theory, it goes up slightly as the tire is compressed, but the overall volume change is negligible.) Since the tire held up almost entirely by air, it retains the same stiffness, no matter how hard you push on it. That makes it more resistant to bottoming out on the rim.

Bottoming out is never desirable, but it can be especially bad with wide rims, because many wide rims are not as strong as narrow rims. To keep the weight in check, many wide rims have super-thin walls. Thanks to their larger profile, stiffness is OK, and the wheel builds up fine—but impact resistance is much lower. Not only is the tire more likely to bottom out, the rim is also more likely to sustain damage when it happens.

Thomas De Gendt’s crash was initially suspected to be caused by a tire that was too wide for the rim. Once the dust had settled, it became clear that the rim itself had broken when it hit some debris on the road. The object that destroyed the rim was never found, suggesting that it was small. (De Gendt crashed on smooth, clean pavement.) The following weekend, during the Strade Bianche on smooth gravel, another Zipp 353 NSW wheelset broke, this time on the bike of Johannes Adamietz. Pushing the envelope with respect to rim width (in relation to tire width) may have contributed to those failures.

Running a supple, O-shaped tire at (slightly) higher pressures results in lower rolling resistance, more comfort and better traction. The overall spring rate is the same as with a U-shaped tire, but more of that spring is made up of air, and less of rubber. That’s what you want.

Tire Support

What about the claims that narrow rims don’t support wide tires well? Do wide tires on narrow rims squirm when you are pushing into corners? In my experience, that’s not a concern. For years, I’ve been running 54 mm-wide tires on rims with an internal width of just 18 mm (above). I like to corner hard, and I’ve pushed the bike to its limits, taking full advantage of the superior cornering traction of the wide rubber. I’ve never felt the tires squirm, whether it’s on ultra-fast paved descents, on gravel, or racing cyclocross.

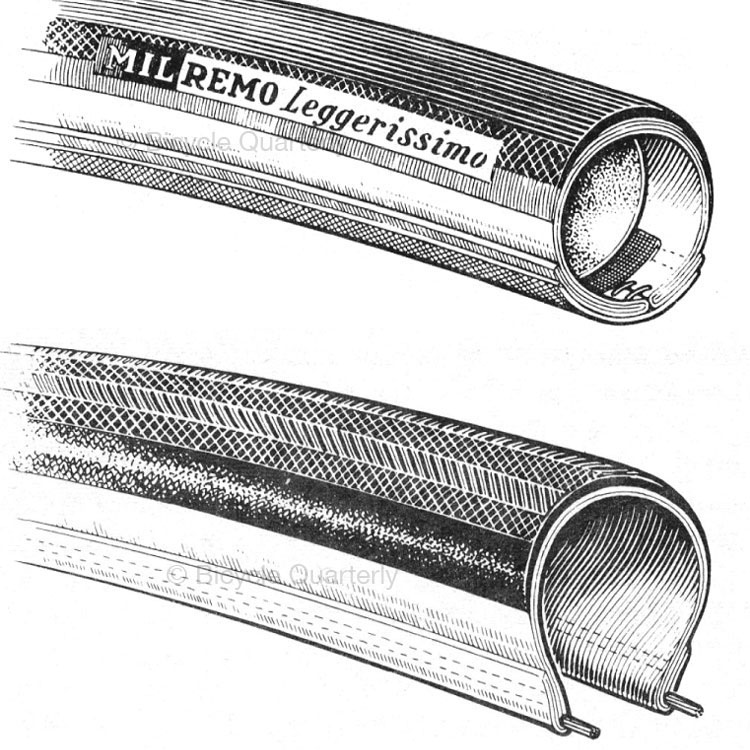

Here is another way to look at this: Envision a tubular tire. Tubulars are the ultimate O-shaped tires (top): They sit entirely on top of the rim. They are glued onto the rim, so they don’t come off easily. That enables tubulars to flex over the entire cross-section, whereas clinchers (lower) are constrained by the rim at the bottom and the lower part of the sides, where the rims wrap around the tire.

You’d expect tubulars to squirm terribly heading into corners. The opposite is true: Whether in road races like the Tour de France or in cyclocross, many top professionals chose tubulars because they offer superb handling. (Many pros have switched to clinchers in recent years, not because tubulars are inferior, but mostly for reasons of marketing. In addition, the advantage of tubulars diminishes as tires get wider.)

Tire Fit and ETRTO / ISO Standards

Should we be concerned about tire fit and safety with ultra-wide rims? The ETRTO / ISO standards exist for a reason. They have been established in close collaboration between tire and rim makers. Combinations that meet the specs are known to be safe—with a significant margin of safety. Going outside those specs, we are in uncharted territory.

Well, not quite. Many tire makers, Rene Herse included, have experimented with wider rims. We know that the margin of safety can be reduced if the fit between tire and rim is excellent. In our experience, Rene Herse tires need to be at least 25% wider than the rim (internal width). Of course, you can go right to the limit with the rim only if it provides excellent tire fit. All Zipp rims we’ve measured were within ETRTO/ISO specs, which is a good sign. This preliminary research suggests that the new 303 XPLR rims are safe with Rene Herse tires ≥40 mm wide—which matches what Zipp recommends for the new rims.

The difficult part is to ensure that all tires of a given model are safe on all 303 XPLR rims—since there are always some variations among individual tires and individual rims. Sidewall hooks add a fail-safe in case the rim dimensions are a little off. The new 303 XPLR rims are hookless, which makes it even more important that the tire/rim fit is perfect. Since before the launch of the new wheels, we’ve been in discussions with Zipp’s engineers about how to ensure safety.

Conclusion

Ultra-wide gravel rims can seem appealing, but the reality doesn’t always live up to expectations. Aero advantages are minor at best, because the rims aren’t deep enough (in relation to the wide tires) to achieve laminar airflow. From a rolling resistance perspective, the lower pressure enabled by the U-shaped tire is canceled out by the greater stiffness of the tire itself. A better way to reduce rolling resistance is running wider tires, which can run at lower pressures without relying on U-shaped tire sidewalls to support the weight of bike/rider.

To keep the weight of ultra-wide rims acceptable, many of these rims have very thin walls, making them vulnerable to impacts. Tire fit is also a concern: In theory, running gravel tires on rims wider than those allowed by the ETRTO / ISO specs should not pose problems with high-quality rims and tires, but a significant amount of testing would be required to ensure safety. If just one tire in ten thousand comes off the rim, that’s totally unacceptable, at least for us at Rene Herse Cycles.

As gravel technology continues to mature, we are excited to see new developments in the rim/tire area. The new 303 XPLR wheels break with the status quo. Hopefully, this will spur a new round of innovation that will bring real benefits where it matters: on the (gravel) road.

If you’re interested in how bikes really work, you’ll like our book The All-Road Bike Revolution with all the research that has changed cycling in recent years. (Available in English, German and Japanese.) Find out why wide tires can be fast, how to find a frame that optimizes your power output, and how to get a bike that handles like an extension of your body. More information is here.

References:

- Zipp’s aero claims about their SL 70 Aero wing-shaped handlebars

- Escape Collective test of the new 303 XPLR wheels

- Bike Radar test of the 303 XPLR wheels

- Aerodynamics of gravel bikes

Image credits: SRAM/Zipp (top image); Daniel Rebour (Image 7)