TPU Tubes, Saddles and a New Tire

It’s been a busy week here at Rene Herse Cycles. Which is just as well, since the rains have started with a vengeance here in the Pacific Northwest… Time to focus on organizing all the shipments that have come in, on new builds and overhauling existing bikes, and on spending time with family and friends.

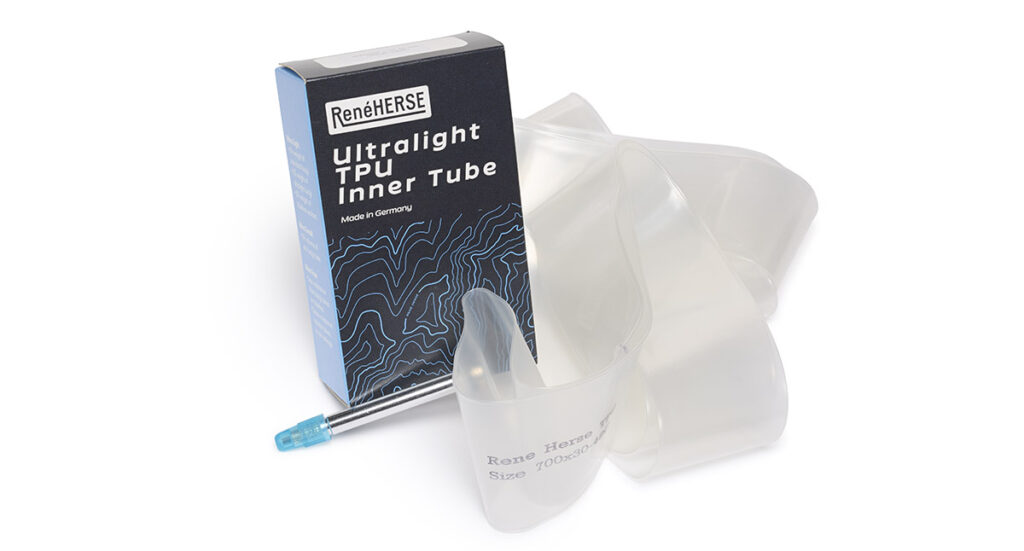

So what has come in? First, the long-awaited TPU tubes are here. A lot of them have already been shipped out to customers who pre-ordered theirs. For now, all models remain in stock. More patch kits have also arrived. (We’re seeing very few repeat sales of patch kits—these tubes flat much less than butyl tubes.)

If you’re thinking of converting your tubeless setup to TPU tubes for the cold season, we’ve got what you need. Why wouldn’t you run your tires tubeless when it’s cold? Latex sealant doesn’t cure well below 40°F (5°C). If you’ve ever tried to paint the exterior of a house with latex paint when it was cold outside, you know what I’m talking about: The paint doesn’t dry. It stays tacky for weeks. The same happens with latex sealant—instead of coagulating quickly and plugging the hole in the tire, it just keeps gushing out.

What about special cold-weather sealant? Those sealants contain anti-freeze components, which addresses another problem: If it’s really cold, the sealant inside the tires can freeze. Then you’ve got solid ice inside your tires—not what you want! However, the anti-freeze doesn’t improve how latex coagulates, so it’s no better at sealing punctures in cold weather than standard sealant. (We spent a lot of time studying sealant when we developed the Rene Herse Supple Sealant…)

You can still ride tubeless tires in cold weather, of course, but the biggest advantage of tubeless—sealing punctures—no longer works reliably. That’s why it’s often better to install tubes for the cold season. Rene Herse TPU tubes are stronger, lighter and faster-rolling than butyl tubes, making them a great choice year-round.

A shipment from Germany included more great components for the dark and cold season. The forged Drust taillight mounts weigh just 1 g each, yet they are ultra-strong. That’s because they are forged (and not CNC-machined or cast), which aligns the grain structure of the metal so it follows the shape of the part. That’s how those little arms can be so tiny… (That’s also the reason why Rene Herse cranks can be so slender and light compared to CNC cranks.)

The Drust light mounts are designed specifically for mounting the minimalist B&M μ (Micro) taillight. We got those back in stock, too. Taillights and mounts are available in black or silver. We also got all models of the superb SON generator hubs back in stock.

Another shipment came from France. This one includes Ted King’s favorite mirror, the Berthoud bar-end mirror. It’s tiny and unobtrusive, yet it gives you a great view of what’s behind. And we all know: Constant awareness of what’s going on around us is essential for our safety as cyclists.

Machined from aluminum in small batches, the mirrors are available in silver and black. The limited quantity we just received are already selling fast—get yours while they last.

I’ve been using Berthoud leather saddles on all my bikes for many years now. Whether Paris-Brest-Paris, Unbound XL or the Arkansas High Country Race, their superior comfort is essential for me. For me, it’s not enough to just finish these long events—I want to have fun doing it! The superlight Galibier saddle in the photo above has done the Oregon Outback (twice), Unbound XL, Ted King’s Xlent Adventure, and many other great rides—and it’s still going strong.

And if it ever wears out, I’m covered: Berthoud saddles are fully rebuildable. All you need is an Allen and a Torx wrench. Of course, that doesn’t really mean anything unless the spare parts are available. Few companies carry them, since they are rarely needed and thus not profitable. At Rene Herse Cycles, we believe in supporting you long after your initial purchase. We’ve got all saddles and all spare parts, including leather tops, bolts and rails, in stock.

Speaking of Berthoud—while organizing the new shipments, we found two Berthoud handlebar bags (GB 22, no side pockets). We are offering them at 25% discount.

What about the new tire mentioned in the headline? That refers to our 700C x 48 Hatcher Pass with the Endurance Plus casing. Gravel riders are moving to wider and wider tires, and we’ve had a number of requests from our pro racers for these tires.

The Endurance Plus casing is truly extraordinary. It features ultra-strong threads and a reinforcement layer that stretches all the way around the tire, from bead to bead. We can confidently say that these are among the toughest gravel tires you’ll find anywhere, yet Endurance Plus tires roll much faster than other reinforced tires. You may wonder: What is the secret, and why don’t other makers offer tires with similar casings? There are two reasons.

First, our R&D. We use real-road tests to figure out what works in the real world, not just in lab tests. Both the speed and cut resistance of these tires has been optimized in the field, over 10,000 miles of testing by pro riders like Ted King, Brennan Wertz, Sofiane Sehili and others.

The second reason why nobody else is making tires like our Endurance Plus is cost: The ultra-strong, yet supple casing fabrics cost more—a lot more—than the materials usually used for tires. The price of the materials isn’t all of it: Making a lightweight tire with these materials is difficult and requires highly skilled craftspeople. Otherwise, the reject rate will be unacceptably high. Our tires are made in Japan and Europe by craftspeople with decades of experience. All that costs money, and if we factored in normal overheads like big companies do, these tires would be prohibitively expensive. However, Rene Herse Cycles is a small company, and our overhead is very low. That’s how we can offer these and other expensive-to-make products at acceptable prices.

There’s a reason why we aren’t interested in cutting costs: When we’re out there riding, whether it’s on adventures with friends in the Cascade Mountains or in races like Unbound XL (above), we want the best components, period. And not the components with the highest profit margins. We started making bike parts because nobody made what we needed and wanted for our rides. That has guided us all along, and will continue to guide us in the future.

More information: