We won the test. Why no celebration?

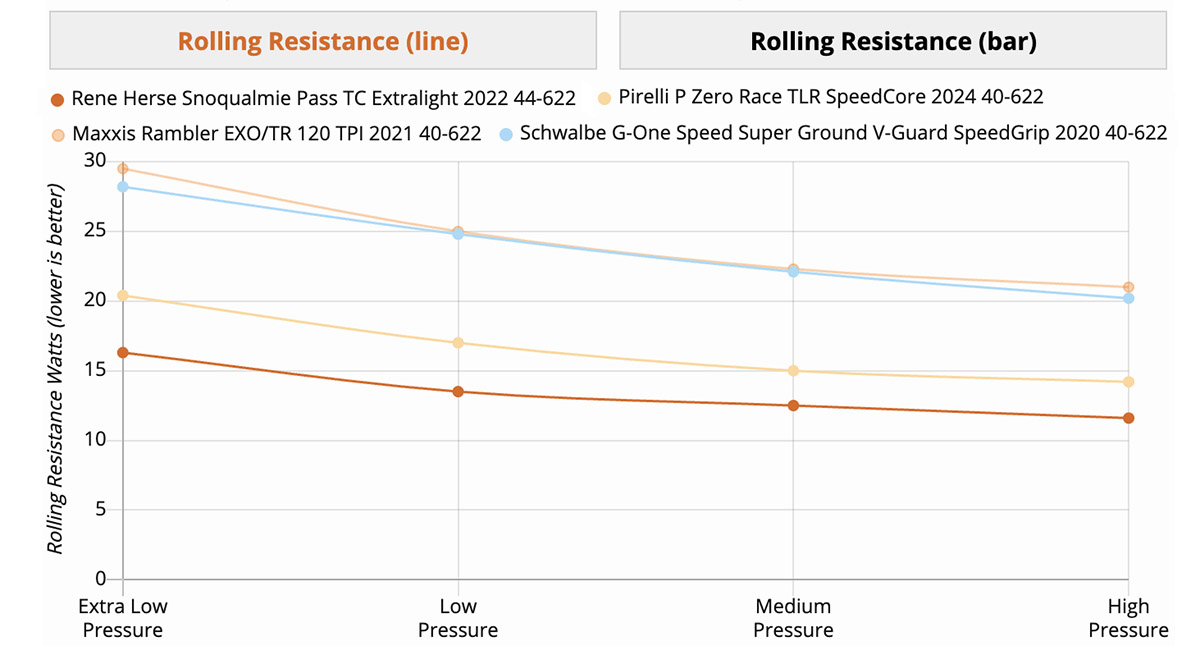

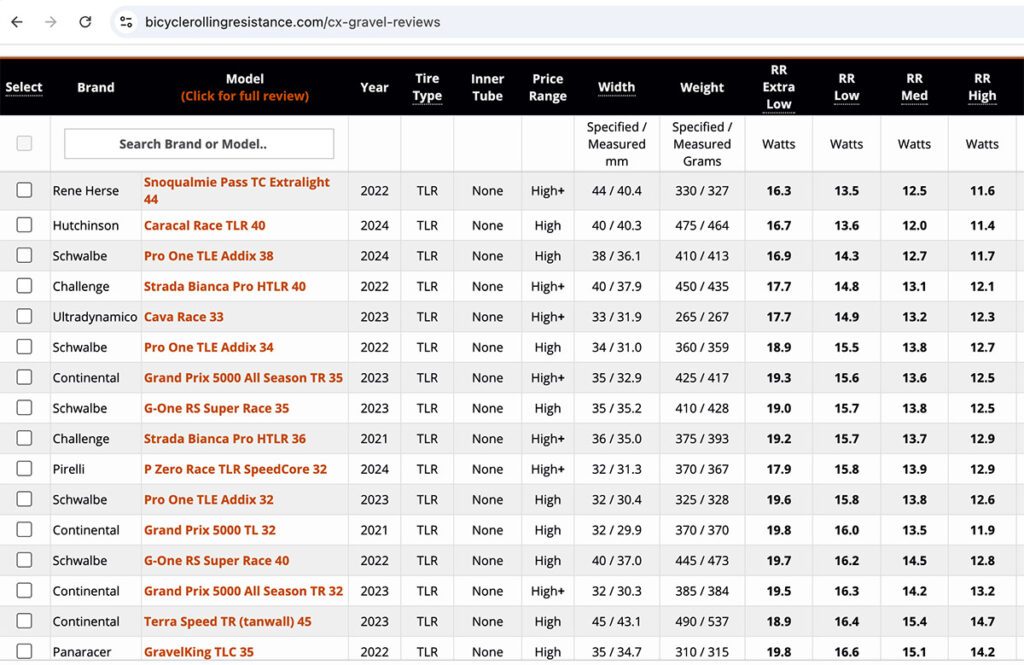

For quite a while now, the Rene Herse 700×44 Snoqualmie Pass has been the fastest wide tire (>32 mm) on www.bicyclerollingresistance.com, a popular website that tests tire performance. Every month, they test new tires—recently Pirelli’s latest P Zero Race TLR SpeedCore that now comes in a 40 mm width—but none roll as fast as the Snoqualmie Pass Extralight.

If we were a normal company, our marketing department would have a field day… But we are a company driven by science, not marketing. (In fact, we don’t even have a marketing department.) And as much as we are happy to win a test—any test—we also know that testing tires on steel drums can be misleading.

That’s not a criticism of this particular website, but it’s inherent in this method of testing tires. For readers who have been following our research, this isn’t anything new. After all, we started making tires after our real-road tire tests showed that there was a better way. Back then, the steel drums were smooth. In an attempt to address concerns about vibrations, some tests now use textured drums. This still can’t measure suspension losses, which are caused by friction of the rider’s body tissues—friction that turns energy into heat and slows the bike down. (Read our article Suspension Losses—The Missing Link for more on this.)

To start, let’s look at why our tires score so well on the steel drum. The answer is simple: Lightweight casings trump almost everything else, even on steel drums. They absorb less energy as they deform with each wheel revolution. That is the reason they roll faster—in the real world and in drum tests. Our tires are among the lightest in their size, and also the fastest.

So far, so good. Things get problematic if we try to optimize our tires further, so they score even better in these drum tests. Apart from supple casings, what makes tires fast in drum tests often makes them slower in the real world. What would this look like?

Tire Pressure

The easiest way to make a tire faster on a steel drum is to increase tire pressure.

Higher Pressure = More Speed (on the drum)

It’s as simple as that. In fact, that’s the main reason narrow racing tires score better than wide gravel tires—on steel drums. That doesn’t just apply to our tires, but all tires.

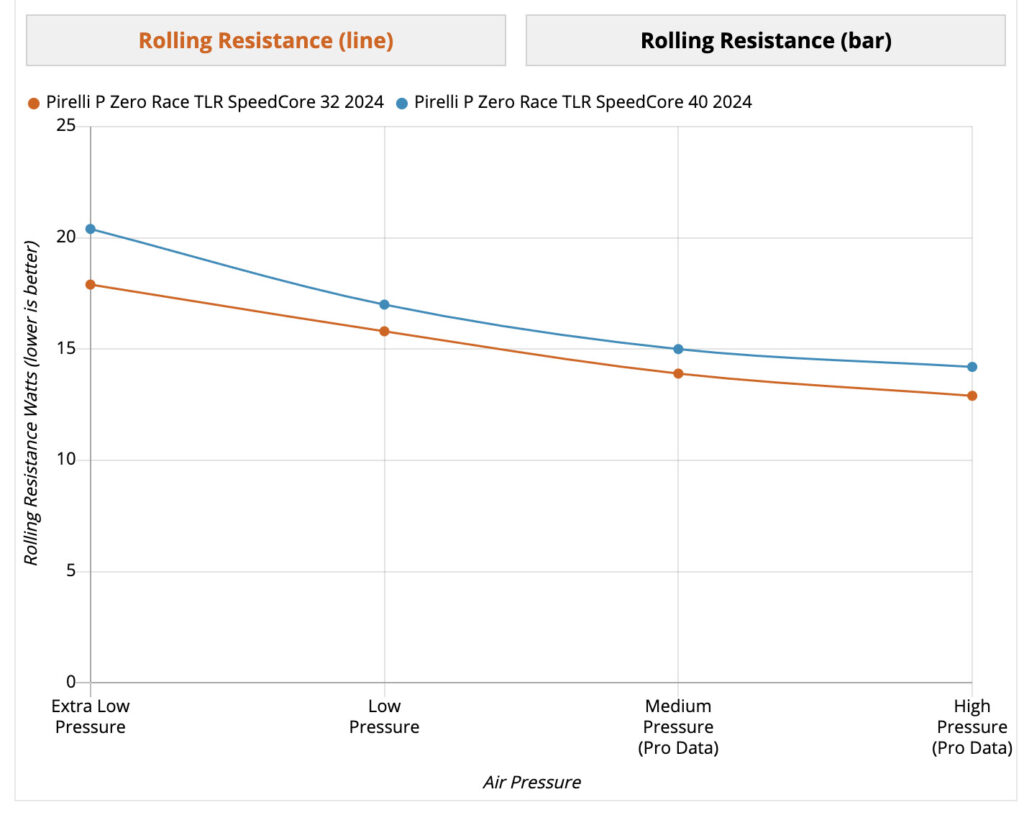

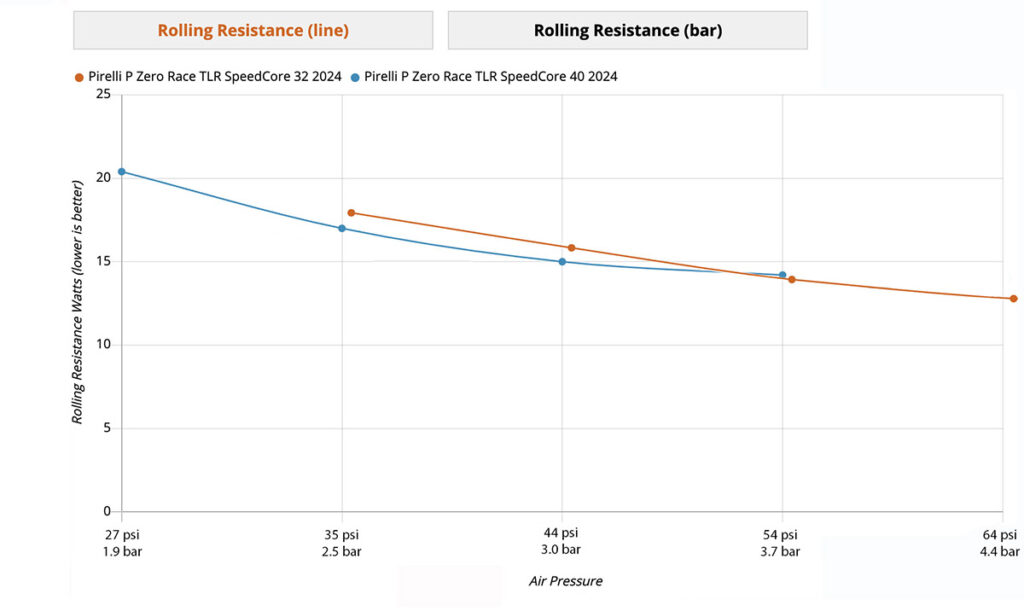

Above are drum tests of the Pirelli P Zero Race TLR SpeedCore, in 32 and 40 mm widths. You see that the 32 mm (red) rolls significantly faster than the 40 mm (blue). What the graph doesn’t show: The narrow tire was tested at higher pressures.

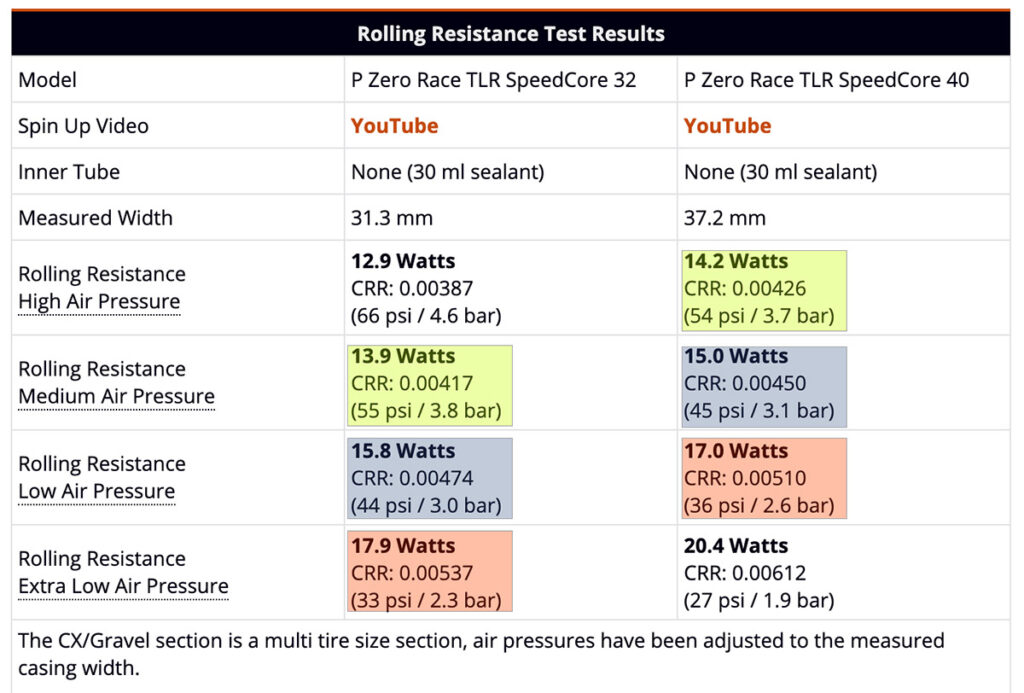

When you look at the actual data, you see that ‘high’ pressure for the 32 mm tire is 66 psi. For the 40 mm tire, ‘high’ pressure is just 54 psi. (For metric units, see the chart above.)

What happens if we compare both tires at the same pressures? We colored the table to make comparison easier: The yellow box shows 54/55 psi; the blue box 44/45 psi; the red box 33/36 psi. ‘Medium’ pressure for the narrow 32 mm tire counts as ‘high’ pressure for the wide 40 mm, and so on.

If we modify the graphs to show actual pressure rather than ‘high, medium, low, extra-low’ (which changes its meaning from tire to tire), we get this:

Look at the pressure range where the two tires overlap: between 35 and 54 psi. The wide 40 mm tire (blue) is as fast or faster than the narrow 32 (red).

Of course, there’s a reason why the original tests run wide tires at lower pressures: That’s how you typically ride them. In fact, the only ‘advantage’ of the narrower 32 mm tire is that you typically run it at higher pressures. And since the max. pressure of the narrower tire is higher, its ultimate speed in the drum test will be higher, too. You wouldn’t run a 40 mm tire at 64 psi, but it’s a reasonable pressure for a 32 mm. And the drum test suggests that, more than anything else, high pressure makes a tire fast. (Note how you ‘save’ 5 watts per tire by increasing the pressure in the 40 mm tires from 27 to 44 psi.)

When drum tests ruled the world of bicycle tires, we inflated our tires to the maximum pressure to get the lowest rolling resistance. And since narrow tires have higher max pressures, we ran narrow tires. It’s what the science that was available back then told us to do. And it’s what drum tests still tell us to do.

Since then, the wide-tire revolution has changed everything. Higher pressures roll faster on steel drums, but not in the real world. Nobody who follows bike tech inflates their tires to the max any longer. Here’s why: One thing we’ve consistently found in our real-road testing is that high pressures don’t roll faster, because they transmit more vibrations and thus result in higher suspension losses.

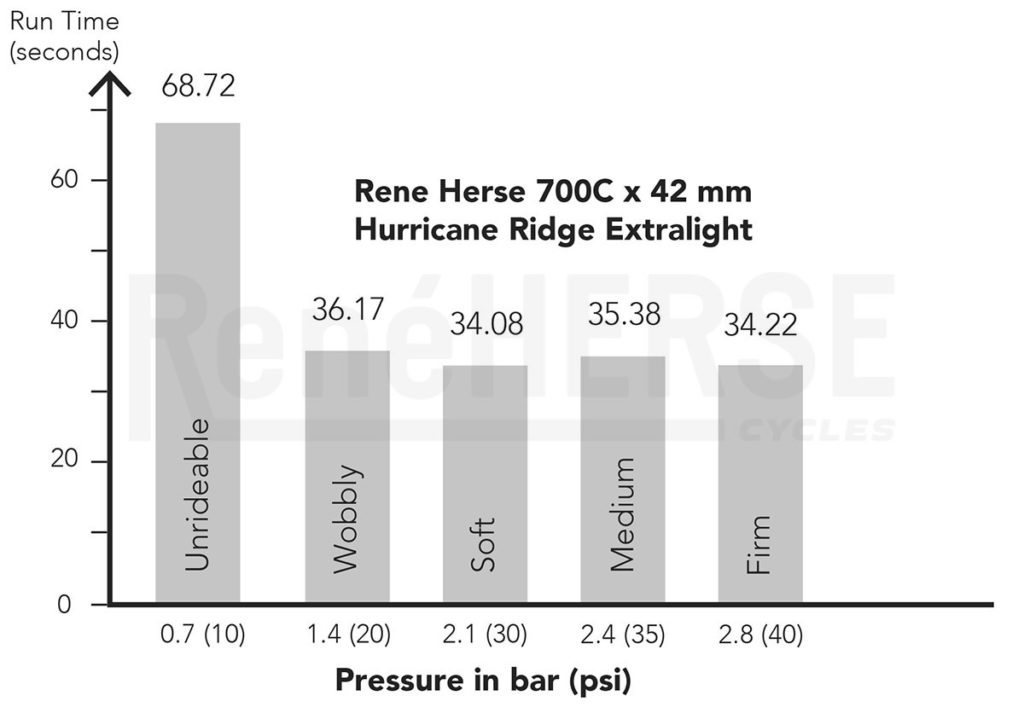

In the roll-down tests above, our 42 mm tires roll as fast at 30 psi as they did at 40 psi. At 20 psi, the pressure was so low that the tires wobbled and were unsafe to ride, yet they rolled almost as fast as they did at higher pressures. At 10 psi, the tire was essentially unrideable. (We managed to test at that pressure because in a roll-down test, we don’t pedal. We also avoided any sudden steering inputs.) At that point, the tire finally slowed down a lot. In other words, as long as you have enough air in your tires so they are rideable, higher pressure does not make you faster:

Higher Pressure ≠ More Speed (on the road)

It’s not just our testing that shows this. When www.cyclingnews.com tested 24 mainstream race tires on the Pedalling Efficiency Rig at the Silverstone Sports Engineering Hub (with a rider on the bike), they concluded: “Changing tyre pressure within a relatively wide margin had no tangible impact on performance.”

Pro cyclists have noted these new findings. If higher pressures made you a lot faster, as the drum tests suggest, pro racers would pump up their tires to the max. They don’t: Tadej Pogačar won almost everything last year, on 30 mm tires that he runs at 57 psi—even though they are rated to 100 psi.

Tire Width

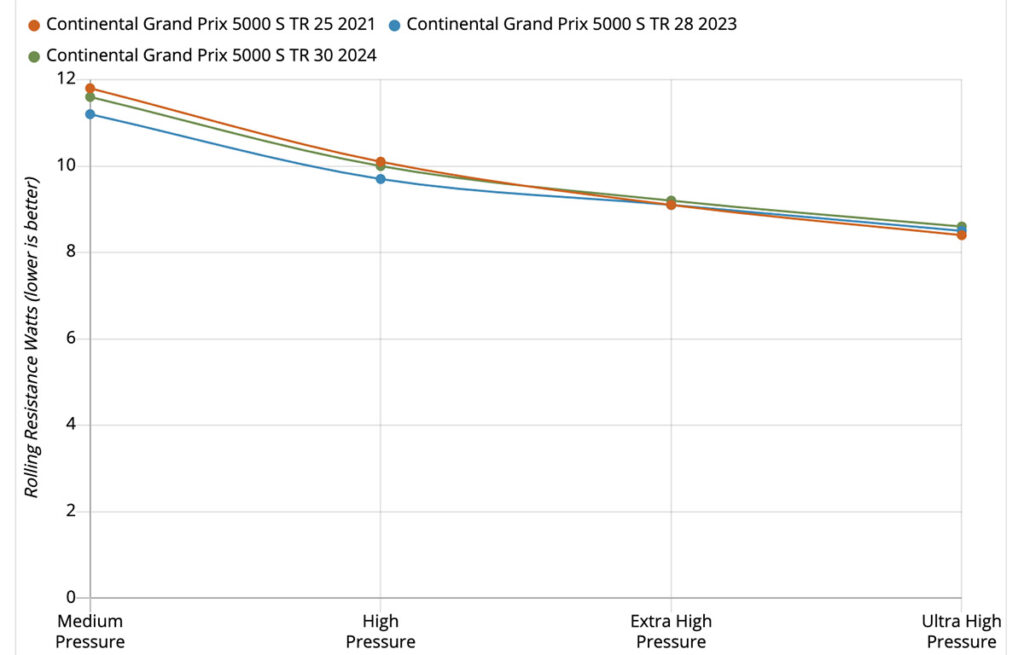

If we believe the drum tests, we have to wonder why Pogačar is running 30 mm tires in the first place. The 25 mm version of his sponsor’s road racing tire is rated to 115 psi!

Based on the drum tests, Pogacar shouldn’t run 30 mm tires at ‘medium’ pressure (57 psi), but 25 mm tires at ‘ultra-high’ pressure (120 psi). He’d save 6.4 watts (for two tires).

Pogačar and his team know that drum tests don’t replicate real-world conditions. What is fast on the steel drum isn’t always fast on the road. The drum tests don’t show the increased vibrations that you get with higher pressures. Those vibrations cause suspension losses that cancel out any gains from reduced tire deformation. Pogačar and his team ignore the results of the drum tests and choose wide tires that offer more grip, are faster on rough road sections, and suffer from fewer punctures—while rolling just as fast as narrower rubber at higher pressures. In fact, Pogačar’s tire pressure is exactly what the Rene Herse Tire Pressure Calculator recommends for his weight and tire width.

Harder Tread Rubber

OK, we already knew that high pressure doesn’t make tires faster in the real world. Some cyclists may be thinking: “Ok, sure, using steel drum tests to figure out optimum tire pressure isn’t going to work. But can’t we at least use the drum tests to compare tires of similar width, at similar pressure? For example, if we’re looking for the fastest 44 mm tire, won’t the steel drum tests show us that?”

We’ll still run into problems. The reason high pressure is faster in the drum tests is simple: It makes the tire harder. There is less flex, which means less energy is lost to hysteresis. The down side of harder tires is that they vibrate more, which increases suspension losses as soon as you add a rider to the system. That doesn’t show up in the drum tests, but, in the real world, it cancels any benefit of the reduced flex.

So to make a tire score better on the steel drum, you want to make it harder. One way, as we’ve seen, is to increase tire pressure. There are other ways to make a tire harder.

For example, we could use a harder rubber compound for the tread. From the perspective of on-the-road performance, we wouldn’t want to do that. A harder tread will transmit more vibrations. It also will be less grippy, because it’s not conforming to the surface well. But a stiffer tire flexes less on the steel drum, so it rolls faster. And since the drum is convex, rather than flat like a real road, the effect of harder rubber is magnified. It’s an open secret among tire makers: If you want to score better in the drum tests, you make your rubber harder.

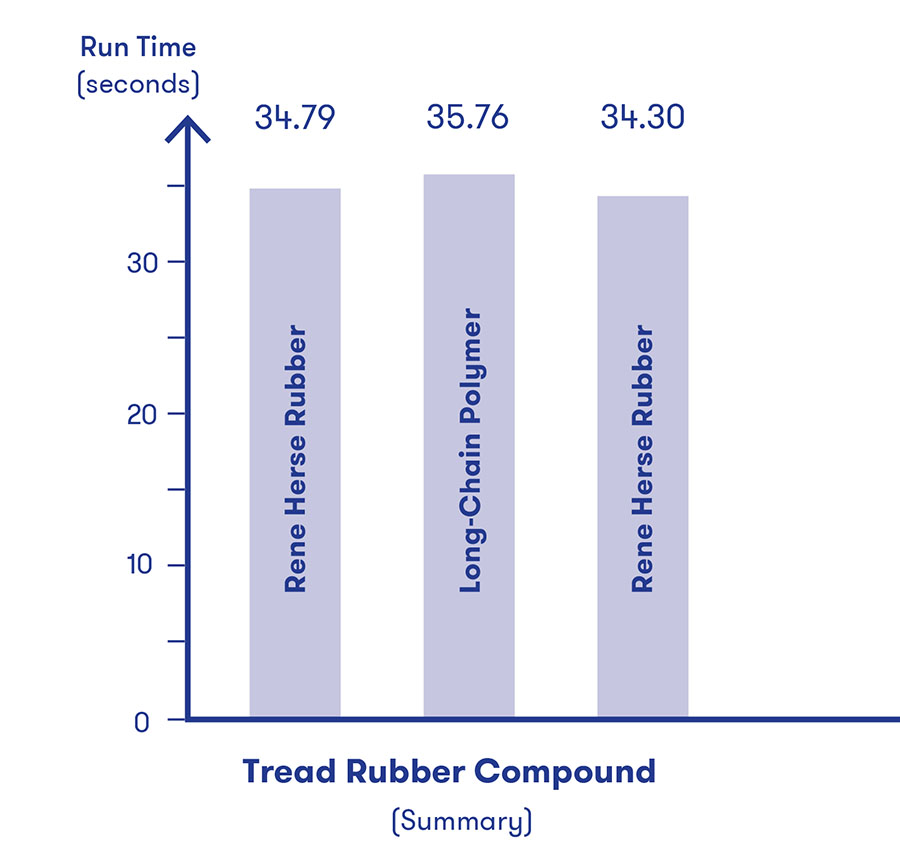

You probably already suspect that a harder tire does not roll better on real roads… We tested that as part of our R&D. A few years ago, tire makers introduced new tread rubber compounds that incoporated long-chain polymers. Marketed under names like ‘Black Chili,’ these new compounds rolled significantly faster in steel drum tests.

Despite all the advertising claims, there is nothing proprietary about long-chain polymers. (That’s why they can’t be patented, so companies invented fancy names that they can trademark.) Any tire maker can buy these ingredients from the big chemical companies that supply the raw materials to all tire manufacturers.

At Rene Herse, we were excited when we heard about this innovation. We constantly develop our tires to make them faster, more comfortable, more puncture-resistant, etc. What’s different is that we test every innovation before we introduce them to our customers—on real roads with a rider on the bike, not just in the lab on steel drums. We made a few samples with long-chain polymer rubber in the tread, so we could test them in direct comparison with our existing tires.

What we found is that the long-chain polymers are slower on real roads, even though they roll faster on the drum. In the test above, you see that we tested the Rene Herse rubber twice—before and after the new tread compound. That’s important, because it allows us to check whether conditions have changed during our testing session. We test only on days with absolutely no wind, constant temperatures, on the same bike and wheels, same rider, with multiple repeats, etc. We do a statistical analysis to make sure that we’re seeing real differences and not just ‘noise’ in the data. (As I mentioned above, we are a company driven by science, not marketing.)

Each bar shows the averages of 4 test runs. The small difference between the first and last runs with the Rene Herse tread was not significant—it’s just inevitable ‘noise’ you get when you measure anything. However, the long-chain polymer was slower—so much that it was statistically significant. In the end, that’s not surprising: A tire with harder rubber will be more buzzy on real roads, and you get more suspension losses.

The harder rubber compound shows you the trouble with testing on steel drums: When you optimize your tires for better performance in the lab, you may actually get worse performance on real roads. In fact, that’s what is happening with narrow road tires, where the rankings in these drum tests have become a major sales point. One maker told me how they recently made their tread rubber harder, and now their tire scores better in these popular tests. I exclaimed: “But harder rubber makes your tires slower in the real world!” They just shrugged their shoulders. Their job is to sell tires.

Convex Drum

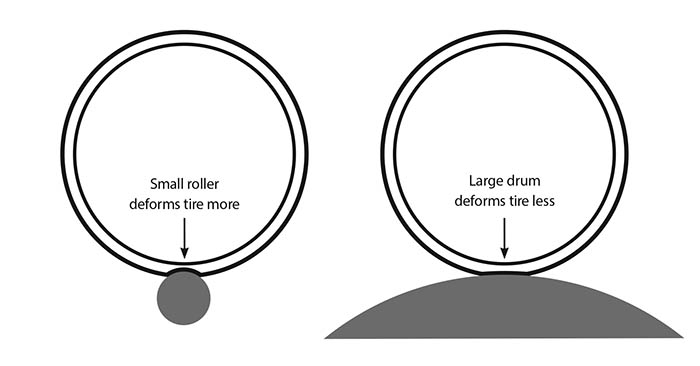

There are other problems with drum tests. One already mentioned above is the convex drum that digs deeper into the tire that a flat road would. The convex drum will deform a stiffer tire less than a more flexible one. This has two main effects on tire design:

- Tires with thick and/or stiff tread roll faster on the drum than they do on the road.

- Large knobs get pushed into the tire casing more on the convex drum than on a flat road. Knobbies that roll fast on the road will roll slowly on the steel drum.

There is a way around this problem: Make the drum so big that it’s essentially flat. Experts generally agree that you’ll need a drum that measures at least 1.8 m (6 ft) in diameter. Unfortunately, such a huge drum is prohibitively expensive even for big tire makers.

Conclusion

Where does all this leave us? You can see why we have mixed feelings when we ace a drum test. It’s nice when our tires are fastest in any test, but we also know we could make them score even higher if we switched to a harder tread compound and used other tricks. But we won’t do that—because making our tires harder wouldn’t just make them slower in the real world, but also buzzier and less fun to ride.

We don’t want to go there, so we don’t pay attention to tests that don’t replicate real world conditions—even if our tires score well in them. We’ll leave it to others to ‘design tires to the test.’ We’ll continue to optimize our tires for real world-performance. If others optimizes their tires for drum tests in the lab, there needs to be somebody who designs their tires so they perform best where it actually matters—on the road.

Further Reading:

- Suspension Losses—The Missing Link

- www.cyclingnews.com test of 24 mainstream race tires on the Pedalling Efficiency Rig. (They didn’t include Rene Herse road tires in the test.)

- How we at Rene Herse test tires on real roads

Photo Credits: www.bicyclerollingresistance.com (RH tire on drum); Will Jones (Pedalling Efficiency Lab); Jered Gruber (Pogačar in yellow); Marc Arjol Rodriguez / Velophoto.tx (Unbound XL)